The Foundation of a Long-Lasting Basketball Court

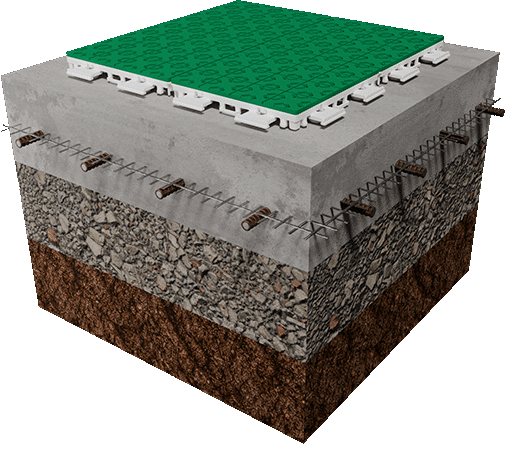

A basketball court is only as good as the surface beneath it. Long before tiles are clipped together or a hoop is installed, the sub-base determines how the court will perform, how long it will last and whether problems appear months or years down the line.

This guide focuses specifically on building the sub-base for a basketball court. It does not cover surface installation or hoop assembly — those steps come later. Getting the foundation right is what allows everything else to work properly.

What Is a Basketball Court Sub-Base?

The sub-base is the engineered foundation that supports the playing surface. Its job is deceptively simple: stay flat, stay stable and manage water. In practice, this means carrying player loads, resisting ground movement and preventing moisture from damaging the court above.

For basketball courts, particularly those using modular flooring, the sub-base must be flatter and more precise than a typical patio, driveway or garden slab. Small deviations that would be acceptable elsewhere can cause problems on a court.

Choosing the Right Type of Sub-Base

Most basketball courts are built on either concrete or asphalt, with concrete being the preferred solution in the majority of installations. It provides a stable, predictable foundation that supports consistent ball bounce and long-term surface performance.

For basketball courts, a reinforced concrete slab should typically meet the following criteria:

- Minimum thickness of 100–150 mm

- Steel mesh or rebar reinforcement

- Laser-levelled finish

- Subtle fall for outdoor drainage

Asphalt bases can be suitable in certain situations, but they require stricter preparation and are more prone to long-term movement.

Flatness and Tolerance Requirements

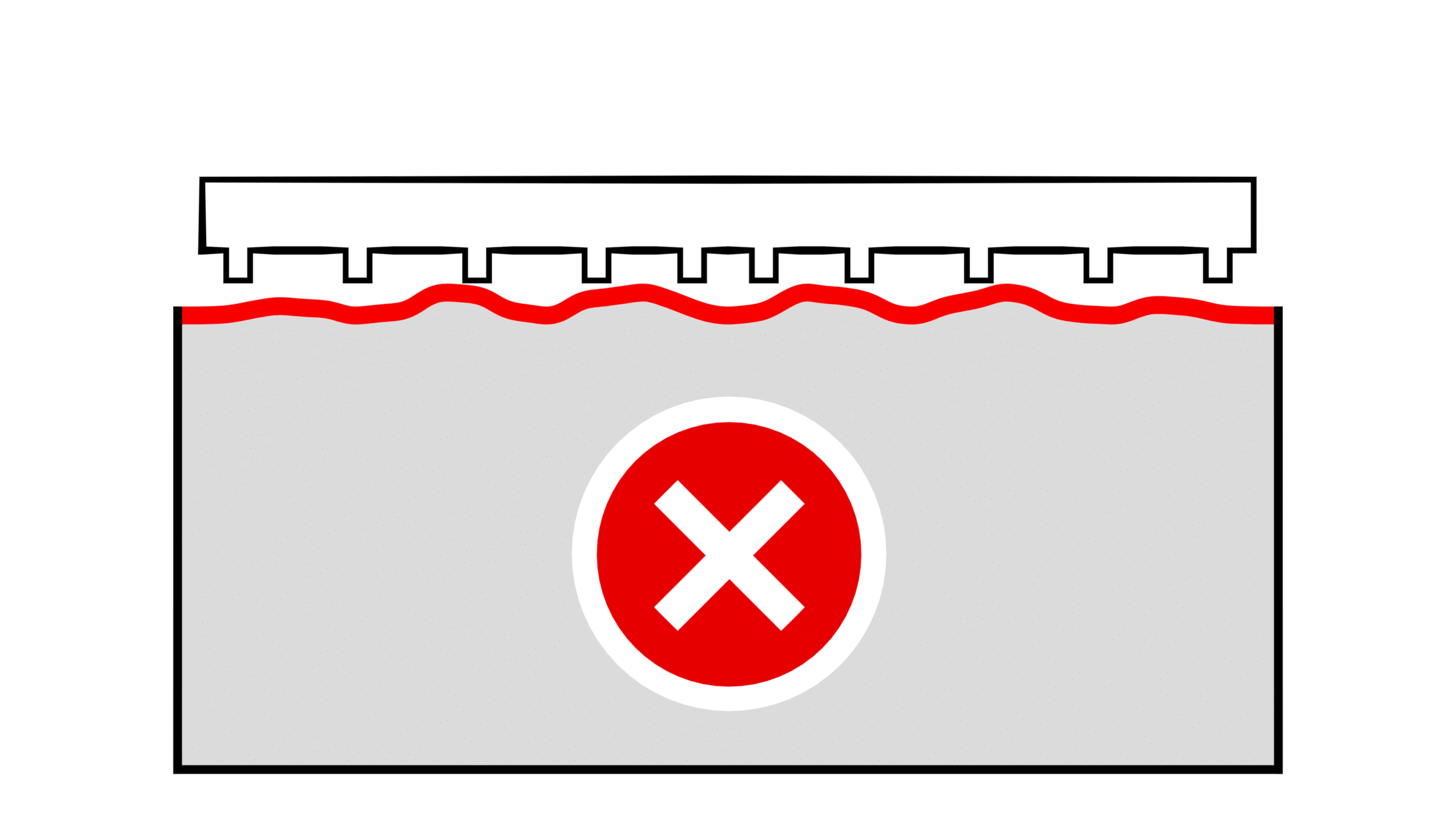

A basketball court surface is unforgiving when it comes to uneven foundations. Unlike paving or general hardscaping, the playing surface amplifies imperfections rather than hiding them. Even minor deviations in the sub-base can affect ball bounce, create uncomfortable footing and make surface installation more difficult.

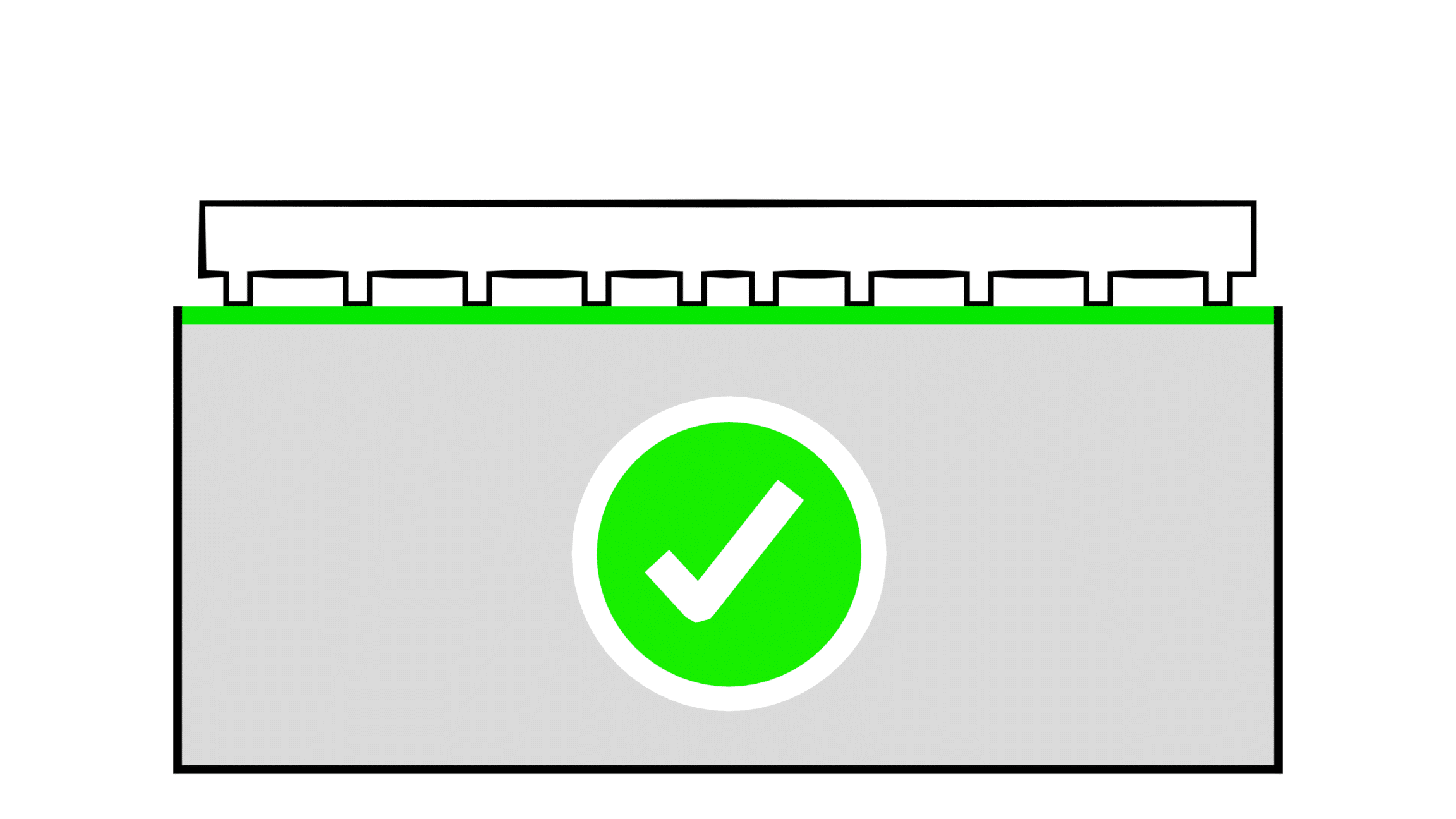

For this reason, basketball courts require a higher standard of flatness than most exterior slabs. The aim is not visual perfection, but consistent performance across the entire playing area. As a practical guide, a basketball court sub-base should meet the following tolerance expectations:

- No more than 3–5 mm deviation over 3 metres

- No abrupt level changes or ridges

- No standing water after rainfall (for outdoor courts)

Meeting these tolerances at the sub-base stage prevents issues that are difficult or impossible to correct once the court surface is installed.

Drainage and Ground Preparation

For outdoor courts, drainage is as important as flatness. Water that cannot escape will eventually cause movement, cracking or frost damage.

Good ground preparation typically involves a compacted stone or hardcore layer beneath the slab, combined with a gentle fall to guide water away from the court area. The goal is not to create a visible slope, but to prevent standing water from forming anywhere on the surface.

Ignoring drainage rarely causes immediate failure — it causes slow, expensive problems later.

Sub-Base Readiness Check

Before you move on to installing your basketball court surface, pause and confirm the following. If you can confidently tick every box, your sub-base is ready.

Your sub-base should be:

- Structurally sound, fully cured and free from cracks

- Flat within basketball court tolerances (no visible dips or ridges)

- Dry, clean and clear of debris

- Properly drained, with no standing water after rainfall

- Built to the correct dimensions and orientation for your court layout

If any of these points are uncertain, resolve them before installing the surface. Fixing issues at this stage is straightforward. Fixing them later is not.

OnCourt provides technical drawings and tolerance guidance for contractors building court sub-bases.

Common Mistakes to Avoid

Most sub-base issues stem from shortcuts rather than bad intentions. Using patio-grade tolerances, skipping reinforcement, pouring without accurate level control or rushing the curing process are all mistakes that compromise the court before it’s even built.

- Using poor tolerances

- No reinforcement

- Pouring without level control

- Installing before full cure

The key principle is simple: fixing sub-base problems after installation is far harder than building it correctly in the first place.

When Is the Sub-Base Ready?

Before moving on to surface installation, the sub-base should be fully cured, clean and structurally sound. It must meet flatness tolerances and show no signs of cracking, movement or soft spots.

Once these conditions are met, installing the court surface and hoop becomes straightforward.

Who Should Build the Sub-Base?

While many basketball court surfaces can be installed DIY, sub-base construction is best handled by experienced groundworks professionals. This stage requires the right equipment, knowledge of local ground conditions and an understanding of tolerance requirements that go beyond general landscaping work.

OnCourt provides technical drawings and specifications so local contractors can build the base correctly without guesswork. This approach combines local expertise with clear performance standards.

Pogosta vprašanja o podlagi za košarkarsko igrišče

Podlaga je utrjena temeljna plast pod površino igrišča. Podpira modularni sistem ploščic, absorbira obremenitve, preprečuje premikanje in zagotavlja enakomeren odskok košarkarske žoge. Brez trdne podlage se igrišče sčasoma lahko premakne, pojavijo se mrtve točke ali slabo odteka voda.

Globina izkopa je odvisna od podlage, talnih razmer in podnebja, vendar običajno znaša od 100 mm do 250 mm. Pri mehki zemlji ali hladnejšem podnebju je morda potrebno izkopati globlje, da se prepreči dvigovanje tal zaradi zmrzali in pogrezanje.

Običajna podlaga za podlago vključuje:

– MOT tipa 1 (drobljen kamen) za utrjevanje in odvodnjavanje

– Plast utrjenega ostrega peska ali tanka slepna plast

– Po želji geotekstilna tkanina za preprečevanje rasti plevela in stabilnost

Za najboljše rezultate pri namestitvi modularnih ploščic uporabite gladko betonsko ali asfaltno podlago. Kot je opisano v tem članku, bo ravnost z odstopanjem največ 5 mm v radiju 3 m zagotovila odlično delovanje.

Podlaga mora biti ravna z odstopanjem največ 5 mm na vsakem 3-metrskem radiju. Ta toleranca je ključnega pomena za zagotovitev, da se modularne ploščice varno zaklenejo in zagotovijo varno in dosledno igralno izkušnjo.

Da. Ustrezno odvodnjavanje je bistveno za preprečevanje zbiranja vode pod modularno površino igrišča. Vključite rahlo naklon, prepustne osnovne plasti ali kanalne odtočne kanale, kot je potrebno za zunanja igrišča.

Da, če ste prepričani v svoje sposobnosti izkopavanja in utrjevanja. Mnogi ljubitelji domačega mojstrstva sami poskrbijo za podlago, vendar za večja ali bolj zapletena igrišča priporočamo sodelovanje s profesionalnim izvajalcem.

Sodelovanje z lokalnim izvajalcem zemeljskih del je običajno pametna izbira. Ti so bolje opremljeni za oceno lokalnih talnih razmer, razumejo regionalne izzive na področju odvodnjavanja in lahko učinkoviteje mobilizirajo ustrezne stroje in materiale. Strokovno pripravljena podlaga vam tudi daje mirno vest, da bo vaše igrišče v prihodnjih letih delovalo najbolje.

Namestitev koša Mega Slam Hoop v tla je dvofazno delo. Najprej je treba izkopati 1,25 m globoko jamo za betonsko sidro, ki bo podpiralo sistem. Naslednja faza je postavitev koša. Koši Mega Slam Hoops so težki – prav to pa jih naredi za najboljše koše za domačo rabo. To pomeni, da boste potrebovali nekaj prijateljev, ki vam bodo pomagali pri dvigovanju težkih bremen. Več informacij o Namestitev Mega Slam Hoops.

OPOMBA – Sistem obročev in pritrdilni elementi morajo biti nameščeni med gradnjo podlage. Konfigurirajte in naročite igrišče, obroče in komponente, da bodo pritrdilni elementi na voljo med gradnjo podlage.

Naslednji koraki

With the sub-base complete, you’re ready to move from groundworks to court assembly.