La base d'un terrain de basket durable

Un terrain de basketball n’est performant que si la surface qui le soutient l’est aussi. Bien avant l’assemblage des dalles ou l’installation du panier, la sous-couche détermine le comportement du terrain, sa durabilité et l’apparition éventuelle de problèmes à court ou long terme.

Ce guide se concentre spécifiquement sur la construction de la sous-couche d’un terrain de basketball. Il ne couvre pas l’installation du revêtement ni l’assemblage du panier — ces étapes interviennent plus tard. Une base correctement réalisée est essentielle pour que tout le reste fonctionne correctement.

Qu’est-ce que la sous-base d’un terrain de basketball ?

La sous-base est la fondation technique qui soutient la surface de jeu. Son rôle semble simple : rester plane, stable et gérer l’eau. En pratique, cela signifie supporter les charges des joueurs, résister aux mouvements du sol et empêcher l’humidité d’endommager le terrain supérieur.

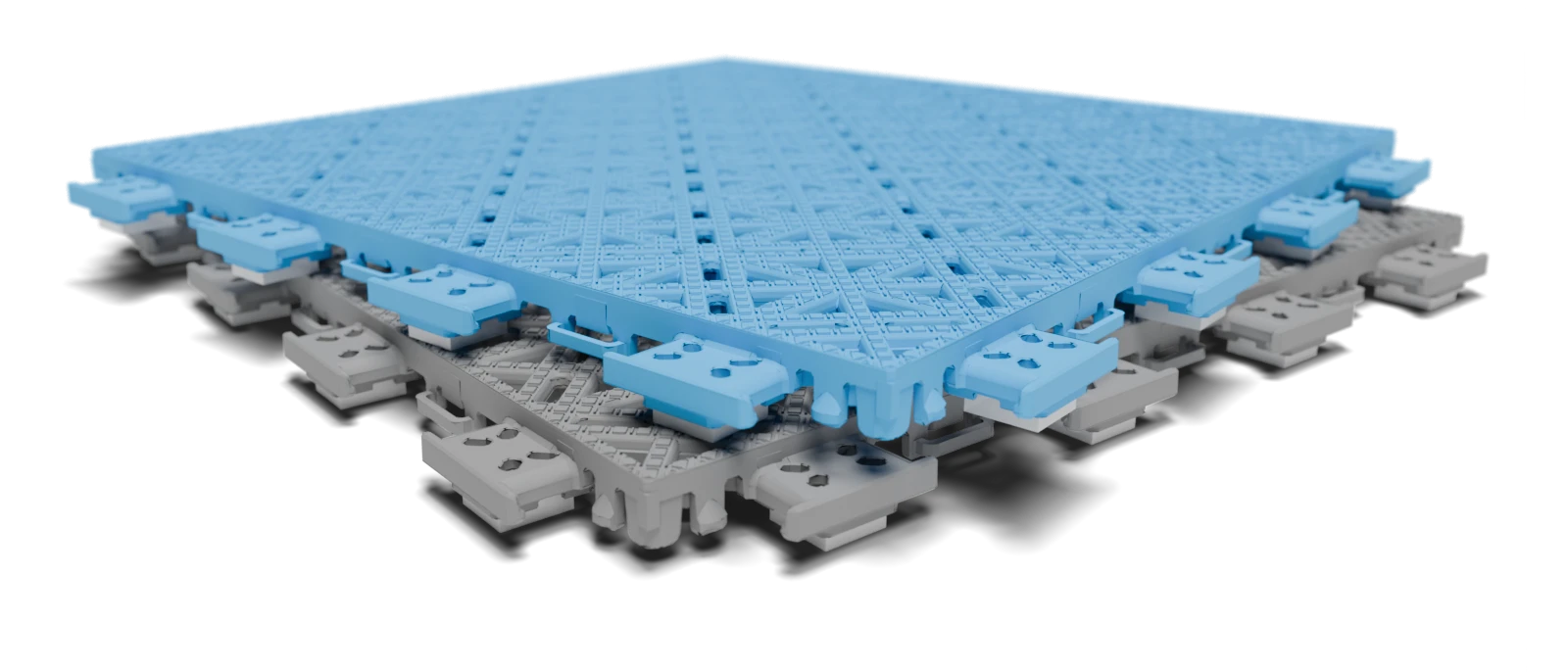

Pour les terrains de basketball, en particulier ceux équipés de revêtements modulaires, la sous-base doit être plus plane et plus précise qu’une terrasse, une allée ou une dalle de jardin classique. De légères irrégularités acceptables ailleurs peuvent poser problème sur un terrain.

Choisir le bon type de sous-base

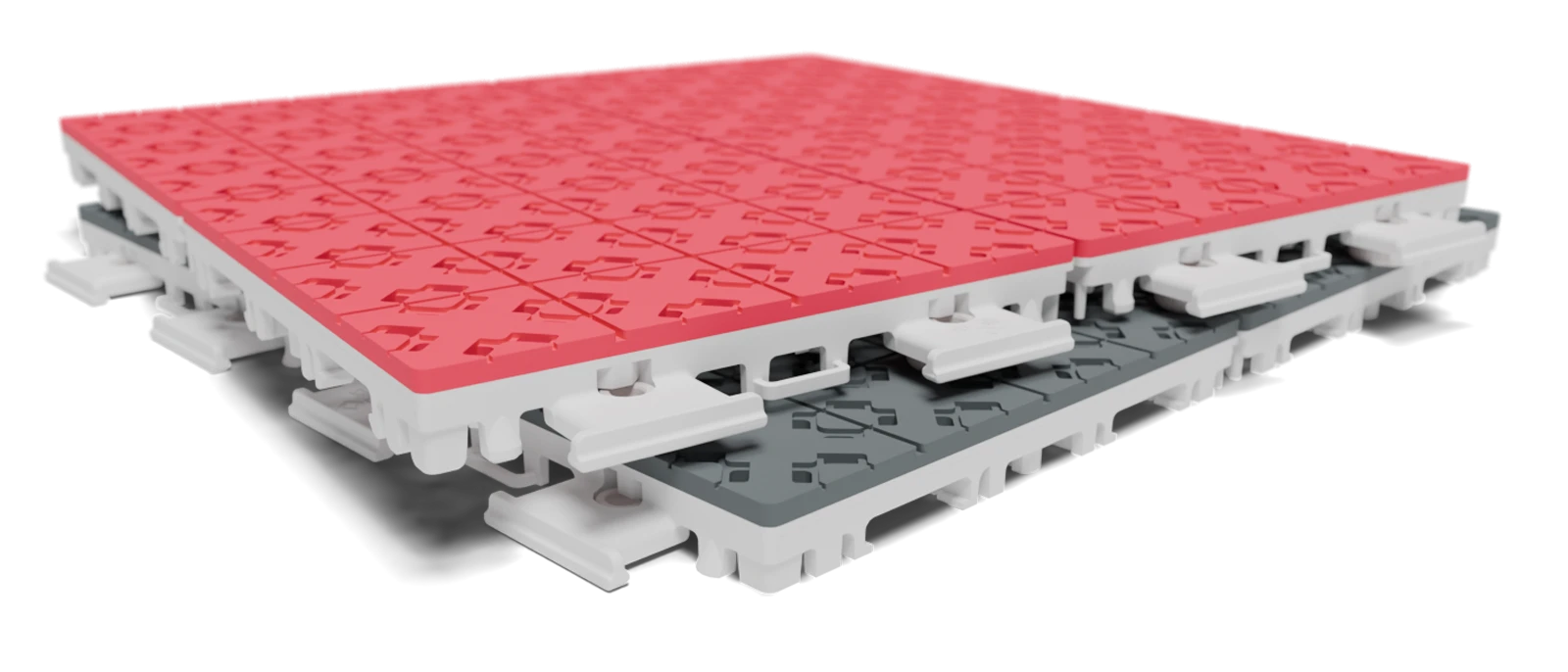

La plupart des terrains de basketball sont construits sur du béton ou de l’asphalte, le béton étant la solution privilégiée dans la majorité des installations. Il offre une base stable et prévisible qui garantit un rebond de balle constant et des performances durables de la surface.

Pour les terrains de basketball, une dalle en béton armé doit généralement répondre aux critères suivants :

- Épaisseur minimale de 100–150 mm

- Armature en treillis métallique ou en barres d’armature

- Finition nivelée au laser

- Légère pente pour le drainage extérieur

Les fondations en asphalte peuvent convenir dans certaines situations, mais elles nécessitent une préparation plus rigoureuse et sont plus sujettes aux mouvements à long terme.

Exigences de planéité et de tolérances

La surface d’un terrain de basketball est impitoyable face à des fondations irrégulières. Contrairement au pavage ou aux aménagements extérieurs classiques, la surface de jeu accentue les imperfections au lieu de les masquer. Même de légères variations de la sous-base peuvent affecter le rebond de la balle, créer un appui inconfortable et compliquer l’installation du revêtement.

Pour cette raison, les terrains de basketball exigent un niveau de planéité supérieur à celui de la plupart des dalles extérieures. L’objectif n’est pas la perfection visuelle, mais des performances constantes sur toute la surface de jeu. À titre indicatif, la sous-base d’un terrain de basketball doit respecter les tolérances suivantes :

- Écart maximal de 3–5 mm sur 3 mètres

- Aucun changement brusque de niveau ni arêtes

- Aucune eau stagnante après la pluie (pour terrains extérieurs)

Le respect de ces tolérances dès la phase de sous-base permet d’éviter des problèmes difficiles, voire impossibles, à corriger une fois la surface installée.

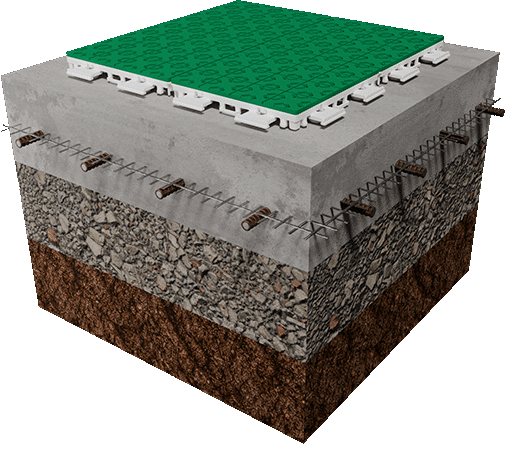

Drainage et préparation du sol

Pour les terrains extérieurs, le drainage est aussi important que la planéité. L’eau qui ne peut pas s’évacuer finira par provoquer des mouvements, des fissures ou des dommages dus au gel.

Une bonne préparation du sol comprend généralement une couche de pierre concassée ou de tout-venant compacté sous la dalle, associée à une légère pente permettant d’évacuer l’eau hors de la zone de jeu. L’objectif n’est pas de créer une pente visible, mais d’éviter toute stagnation d’eau à la surface.

Ignorer le drainage entraîne rarement une défaillance immédiate — cela provoque plutôt des problèmes lents et coûteux à long terme.

Vérification de la préparation de la sous-base

Avant de passer à l’installation de la surface du terrain de basketball, prenez un moment pour vérifier les points suivants. Si vous pouvez cocher chaque case en toute confiance, la sous-base est prête.

Votre sous-base doit être :

- Structurellement saine, entièrement durcie et sans fissures

- Plane dans les tolérances d’un terrain de basketball (sans creux ni arêtes visibles)

- Sèche, propre et exempte de débris

- Correctement drainée, sans eau stagnante après la pluie

- Construite aux dimensions et à l’orientation correctes pour l’agencement du terrain

Si l’un de ces points est incertain, résolvez-le avant d’installer la surface. Corriger les problèmes à ce stade est simple. Plus tard, ce ne le sera pas.

OnCourt fournit des plans techniques et des recommandations de tolérances aux entrepreneurs construisant des sous-bases de terrains.

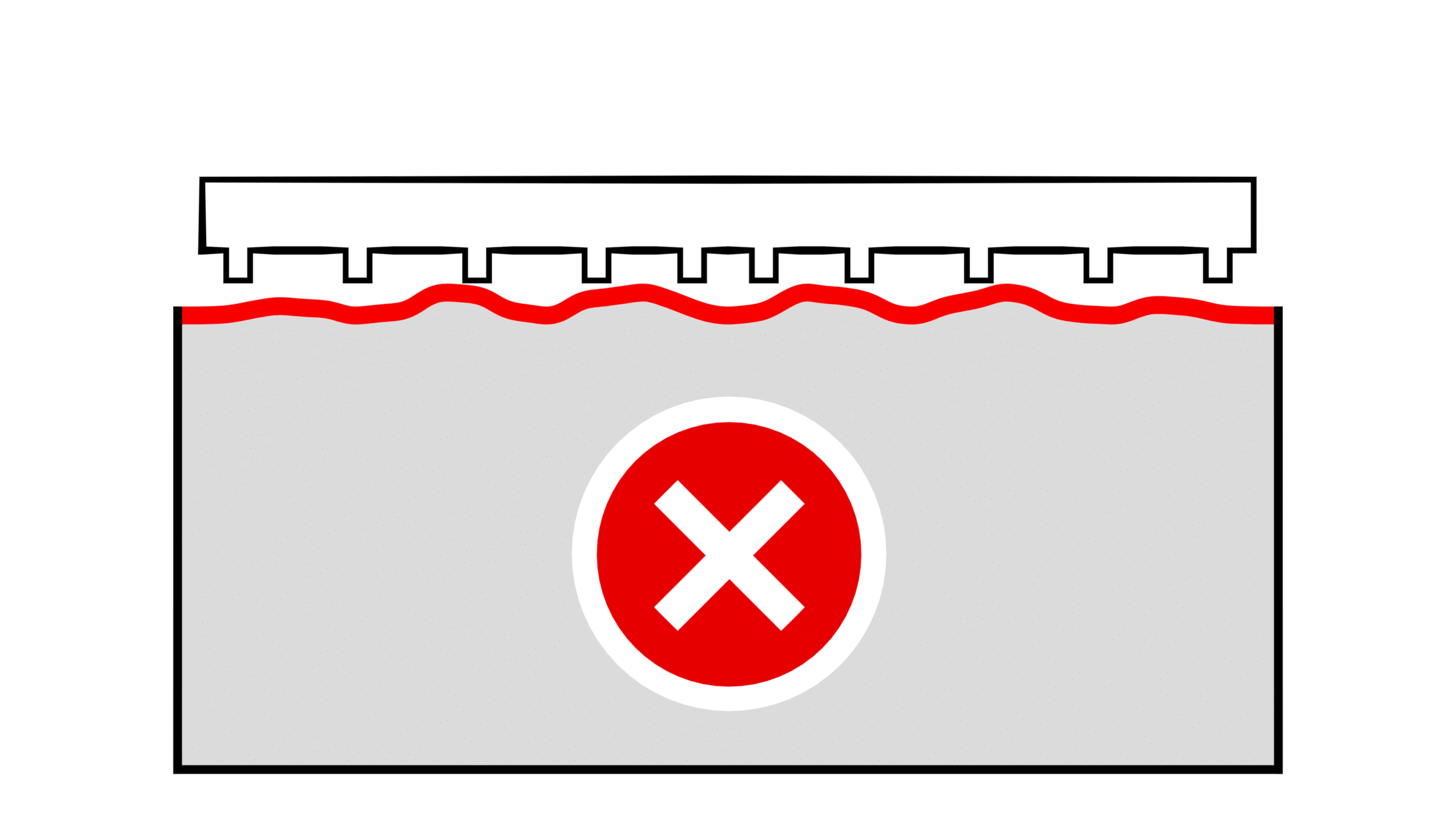

Erreurs courantes à éviter

La plupart des problèmes de sous-base résultent de raccourcis plutôt que de mauvaises intentions. L’utilisation de tolérances de type terrasse, l’absence de ferraillage, le coulage sans contrôle précis du niveau ou un durcissement précipité sont autant d’erreurs qui compromettent le terrain avant même sa réalisation.

- Utilisation de tolérances insuffisantes

- Sans armature

- Coulage sans contrôle précis du niveau

- Installation avant durcissement complet

Le principe clé est simple : corriger les problèmes de sous-base après l’installation est bien plus difficile que de la construire correctement dès le départ.

Quand la sous-base est-elle prête ?

Avant de passer à l’installation de la surface, la sous-base doit être entièrement durcie, propre et structurellement saine. Elle doit respecter les tolérances de planéité et ne présenter aucun signe de fissuration, de mouvement ou de zones molles.

Une fois ces conditions remplies, l’installation de la surface du terrain et du panier devient simple.

Qui doit construire la sous-base ?

Bien que de nombreuses surfaces de terrain de basketball puissent être installées en DIY, la construction de la sous-base est préférable entre les mains de professionnels expérimentés des travaux de terrassement. Cette étape nécessite l’équipement approprié, la connaissance des conditions du sol locales et une compréhension des exigences de tolérance qui dépassent le simple aménagement paysager.

OnCourt fournit des plans techniques et des spécifications afin que les entrepreneurs locaux puissent construire la base correctement, sans approximation. Cette approche associe l’expertise locale à des normes de performance claires.

FAQ sur la sous-base des terrains de basketball

La sous-base est la couche de fondation compactée située sous la surface de votre terrain. Elle soutient le système de dalles modulaires, absorbe la charge, empêche les mouvements et garantit un rebond cohérent du ballon. Sans une sous-base solide, le terrain peut se déplacer, présenter des zones mortes ou avoir un mauvais drainage avec le temps.

La profondeur d’excavation dépend du type de sol, des conditions du terrain et du climat, mais se situe généralement entre 100 mm et 250 mm. Pour les sols meubles ou les climats froids, il peut être nécessaire de creuser plus profondément pour éviter le soulèvement dû au gel et les affaissements.

Une sous-base standard comprend :

– Du gravier concassé de type 1 MOT pour le compactage et le drainage.

– Une couche de sable grossier compacté ou de fine couche de finition.

– Facultativement, un géotextile pour contrôler les mauvaises herbes et stabiliser le sol.

Pour des résultats optimaux, terminez avec une dalle en béton ou en asphalte bien nivelée pour l’installation de dalles sportives modulaires. Comme indiqué dans cet article, une tolérance de planéité de 5 mm sur un rayon de 3 m garantit des performances optimales.

Votre sous-base doit être plane à moins de 5 mm de variation sur un rayon de 3 m. Cette tolérance est essentielle pour que vos dalles modulaires s’emboîtent correctement et garantissent une expérience de jeu sûre et homogène.

Oui. Un bon drainage est essentiel pour éviter la stagnation de l’eau sous la surface du terrain modulaire. Prévoyez une légère pente, des couches de base perméables ou des caniveaux si nécessaire pour les terrains extérieurs.

Oui, si vous êtes à l’aise avec l’excavation et le compactage. De nombreux bricoleurs réalisent eux-mêmes leur sous-base, mais pour des terrains plus grands ou complexes, nous recommandons de faire appel à un entrepreneur professionnel.

Faire appel à un professionnel local du terrassement est souvent le meilleur choix. Il saura évaluer les conditions du sol, anticiper les problèmes de drainage spécifiques à la région, et mobiliser efficacement les bons équipements et matériaux. Une sous-base préparée professionnellement vous assure aussi que votre terrain offrira des performances optimales pendant des années.

L’installation du panier Mega Slam à sceller au sol se fait en deux étapes. Il faut d’abord creuser un trou de 1,25 m de profondeur pour couler un socle en béton qui supportera le système. Ensuite, il faut monter le panier. Les systèmes Mega Slam sont lourds – c’est ce qui les rend si robustes pour un usage domestique. Prévoyez de l’aide pour le levage et l’assemblage. En savoir plus sur Installation de Mega Slam Hoops.

NOTE - Les ancrages du panier et des composants doivent être installés pendant la construction de la sous-base. Configurez et commandez votre terrain, panier et accessoires à l’avance pour que les ancrages soient prêts à être posés pendant cette étape.

Étapes suivantes

Une fois la sous-base terminée, vous pouvez passer des travaux de terrassement à l’assemblage du terrain.