The Foundation of a Long-Lasting Basketball Court

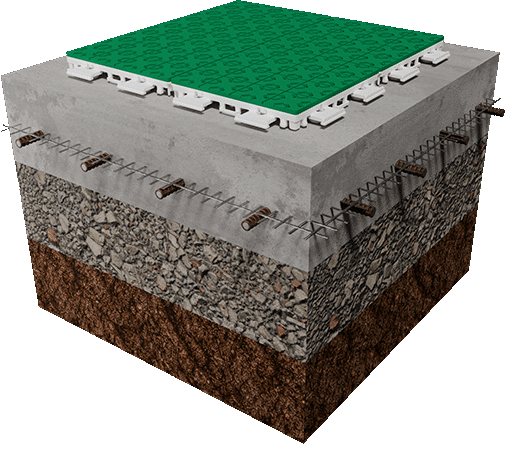

A basketball court is only as good as the surface beneath it. Long before tiles are clipped together or a hoop is installed, the sub-base determines how the court will perform, how long it will last and whether problems appear months or years down the line.

This guide focuses specifically on building the sub-base for a basketball court. It does not cover surface installation or hoop assembly — those steps come later. Getting the foundation right is what allows everything else to work properly.

What Is a Basketball Court Sub-Base?

The sub-base is the engineered foundation that supports the playing surface. Its job is deceptively simple: stay flat, stay stable and manage water. In practice, this means carrying player loads, resisting ground movement and preventing moisture from damaging the court above.

For basketball courts, particularly those using modular flooring, the sub-base must be flatter and more precise than a typical patio, driveway or garden slab. Small deviations that would be acceptable elsewhere can cause problems on a court.

Choosing the Right Type of Sub-Base

Most basketball courts are built on either concrete or asphalt, with concrete being the preferred solution in the majority of installations. It provides a stable, predictable foundation that supports consistent ball bounce and long-term surface performance.

For basketball courts, a reinforced concrete slab should typically meet the following criteria:

- Minimum thickness of 100–150 mm

- Steel mesh or rebar reinforcement

- Laser-levelled finish

- Subtle fall for outdoor drainage

Asphalt bases can be suitable in certain situations, but they require stricter preparation and are more prone to long-term movement.

Flatness and Tolerance Requirements

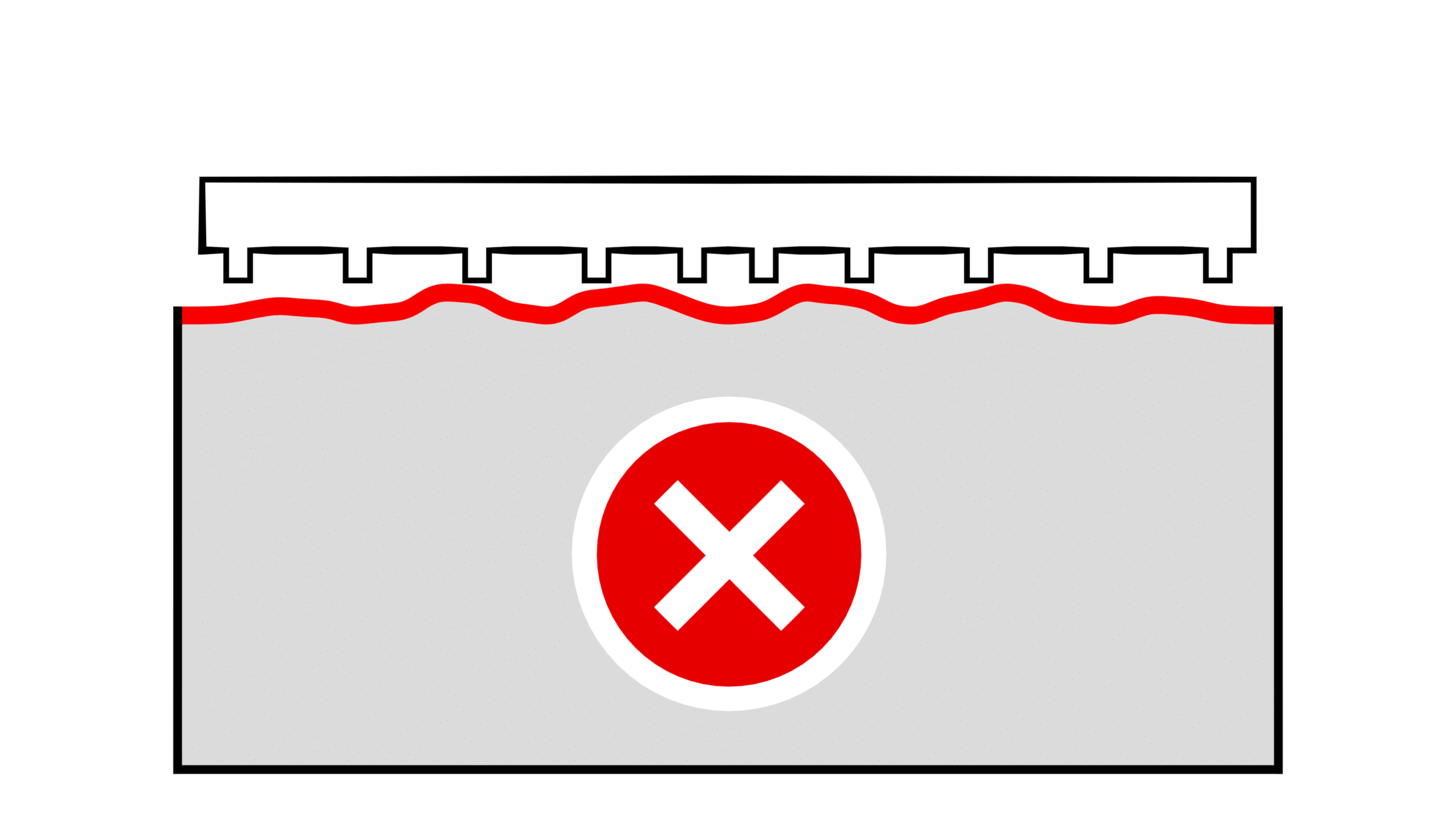

A basketball court surface is unforgiving when it comes to uneven foundations. Unlike paving or general hardscaping, the playing surface amplifies imperfections rather than hiding them. Even minor deviations in the sub-base can affect ball bounce, create uncomfortable footing and make surface installation more difficult.

For this reason, basketball courts require a higher standard of flatness than most exterior slabs. The aim is not visual perfection, but consistent performance across the entire playing area. As a practical guide, a basketball court sub-base should meet the following tolerance expectations:

- No more than 3–5 mm deviation over 3 metres

- No abrupt level changes or ridges

- No standing water after rainfall (for outdoor courts)

Meeting these tolerances at the sub-base stage prevents issues that are difficult or impossible to correct once the court surface is installed.

Drainage and Ground Preparation

For outdoor courts, drainage is as important as flatness. Water that cannot escape will eventually cause movement, cracking or frost damage.

Good ground preparation typically involves a compacted stone or hardcore layer beneath the slab, combined with a gentle fall to guide water away from the court area. The goal is not to create a visible slope, but to prevent standing water from forming anywhere on the surface.

Ignoring drainage rarely causes immediate failure — it causes slow, expensive problems later.

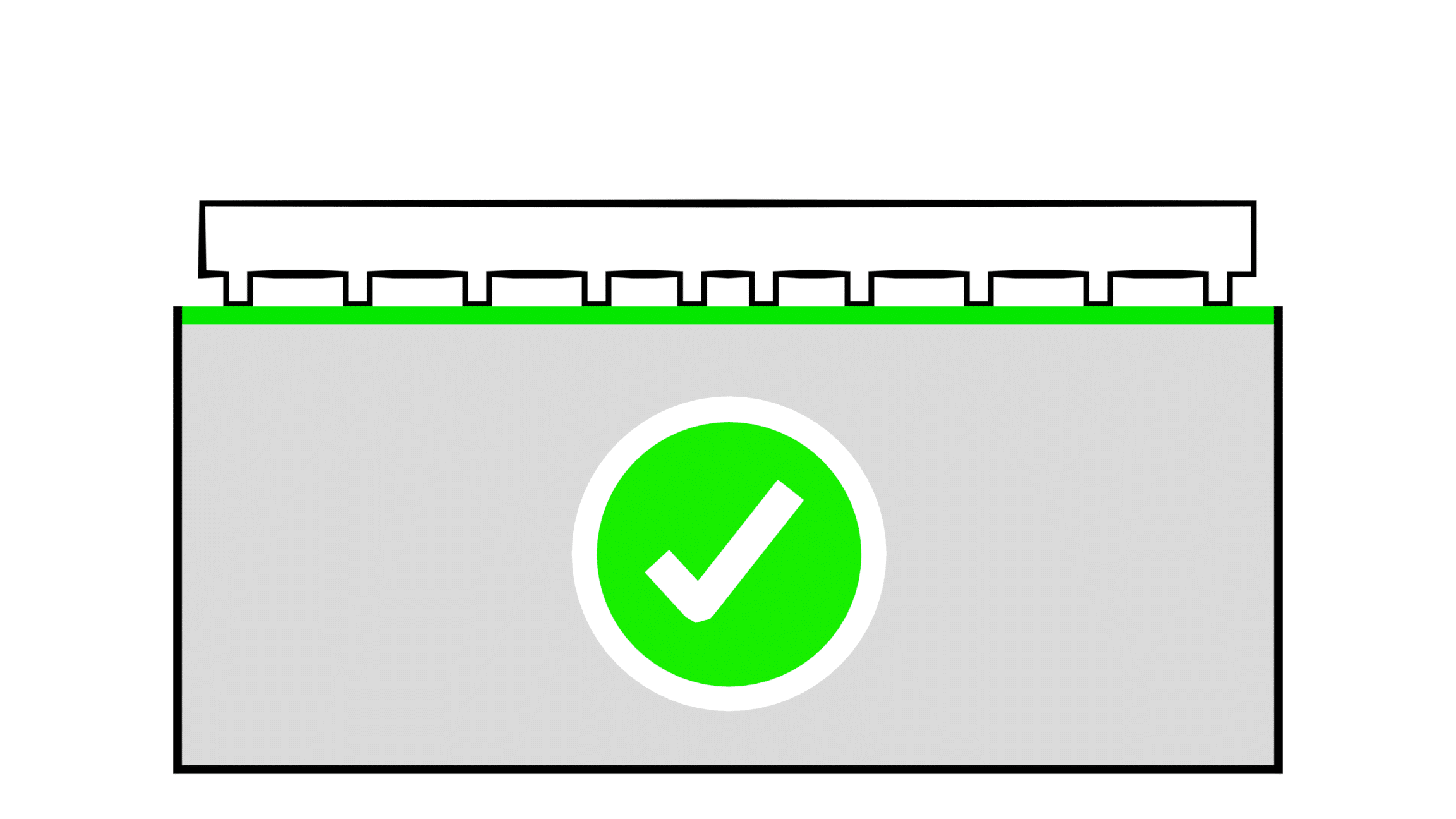

Sub-Base Readiness Check

Before you move on to installing your basketball court surface, pause and confirm the following. If you can confidently tick every box, your sub-base is ready.

Your sub-base should be:

- Structurally sound, fully cured and free from cracks

- Flat within basketball court tolerances (no visible dips or ridges)

- Dry, clean and clear of debris

- Properly drained, with no standing water after rainfall

- Built to the correct dimensions and orientation for your court layout

If any of these points are uncertain, resolve them before installing the surface. Fixing issues at this stage is straightforward. Fixing them later is not.

OnCourt provides technical drawings and tolerance guidance for contractors building court sub-bases.

Common Mistakes to Avoid

Most sub-base issues stem from shortcuts rather than bad intentions. Using patio-grade tolerances, skipping reinforcement, pouring without accurate level control or rushing the curing process are all mistakes that compromise the court before it’s even built.

- Using poor tolerances

- No reinforcement

- Pouring without level control

- Installing before full cure

The key principle is simple: fixing sub-base problems after installation is far harder than building it correctly in the first place.

When Is the Sub-Base Ready?

Before moving on to surface installation, the sub-base should be fully cured, clean and structurally sound. It must meet flatness tolerances and show no signs of cracking, movement or soft spots.

Once these conditions are met, installing the court surface and hoop becomes straightforward.

Who Should Build the Sub-Base?

While many basketball court surfaces can be installed DIY, sub-base construction is best handled by experienced groundworks professionals. This stage requires the right equipment, knowledge of local ground conditions and an understanding of tolerance requirements that go beyond general landscaping work.

OnCourt provides technical drawings and specifications so local contractors can build the base correctly without guesswork. This approach combines local expertise with clear performance standards.

Ofte stillede spørgsmål om underlag til basketballbaner

Underlaget er det kompakte fundamentlag under din banes overflade. Det støtter det modulære flisesystem, absorberer belastning, forhindrer bevægelse og sikrer ensartet boldopspring. Uden et solidt underlag kan banen forskyde sig, få døde zoner eller dræne dårligt over tid.

Udgravningsdybden afhænger af underlag, jordbundsforhold og klima, men ligger typisk mellem 100 mm og 250 mm. Ved blød jord eller koldere klima kan det være nødvendigt at grave dybere for at undgå frosthævninger og sætninger.

Et almindeligt underlag inkluderer:

– Type 1 MOT (knust sten) for komprimering og dræning.

– Et lag komprimeret skarpt sand eller fint afretningslag.

– Eventuelt geotekstil til ukrudtskontrol og stabilitet.

For bedste resultat, afslut med en glat beton- eller asfaltplade ved installation af modulfliser. Som nævnt i artiklen bør planhedstolerancen ikke overstige 5 mm inden for en radius på 3 m for optimal ydeevne.

Din underbase skal være plan med en tolerance på højst 5 mm over en radius på 3 m. Denne tolerance er afgørende for, at dine modulfliser låser korrekt og giver en sikker og ensartet spilleoplevelse.

Ja. Korrekt dræning er afgørende for at undgå vandansamling under det modulære banedæk. Indarbejd en let hældning, permeable lag eller drænrør efter behov til udendørsbaner.

Ja, hvis du har erfaring med udgravning og komprimering. Mange gør-det-selv-folk klarer underlaget selv, men ved større eller mere komplekse baner anbefaler vi en professionel entreprenør.

En lokal entreprenør er ofte det kloge valg. De forstår lokale jordforhold, dræningsudfordringer og har det rette udstyr og materialer. Et professionelt underlag giver dig ro i sindet og langvarig ydeevne.

Installationen af en “in-ground” Mega Slam Hoop består af to faser. Først graves et 1,25 m dybt hul til betonankeret, som holder systemet. Næste trin er at samle selve kurven. Mega Slam Hoops er tunge – det er derfor, de er de bedste til hjemmebrug. Du får brug for venner til at hjælpe med det tunge løft. Læs mere om Mega Slam Hoops installation.

NB - Ankersystemer til kurv og komponenter skal installeres under opbygning af underlaget. Konfigurer og bestil din bane, kurv og dele, så ankerne er klar ved udgravning.

Næste skridt

With the sub-base complete, you’re ready to move from groundworks to court assembly.