A base de um campo de basquetebol duradouro

Um campo de basquetebol é tão bom quanto a superfície por baixo dele. Muito antes de as placas serem encaixadas ou o cesto instalado, a sub-base determina o desempenho do campo, a sua durabilidade e se surgirão problemas meses ou anos mais tarde.

Este guia foca-se especificamente na construção da sub-base para um campo de basquetebol. Não aborda a instalação da superfície nem a montagem do cesto — essas etapas vêm mais tarde. Uma base bem executada é o que permite que tudo o resto funcione corretamente.

O que é a sub-base de um campo de basquetebol?

A sub-base é a fundação projetada que suporta a superfície de jogo. A sua função parece simples: manter-se plana, estável e gerir a água. Na prática, isso significa suportar as cargas dos jogadores, resistir aos movimentos do solo e impedir que a humidade danifique o campo superior.

Nos campos de basquetebol, especialmente aqueles com pavimento modular, a sub-base deve ser mais plana e precisa do que uma varanda, acesso de veículos ou laje de jardim típica. Pequenas variações que seriam aceitáveis noutros contextos podem causar problemas no campo.

Escolher o tipo certo de sub-base

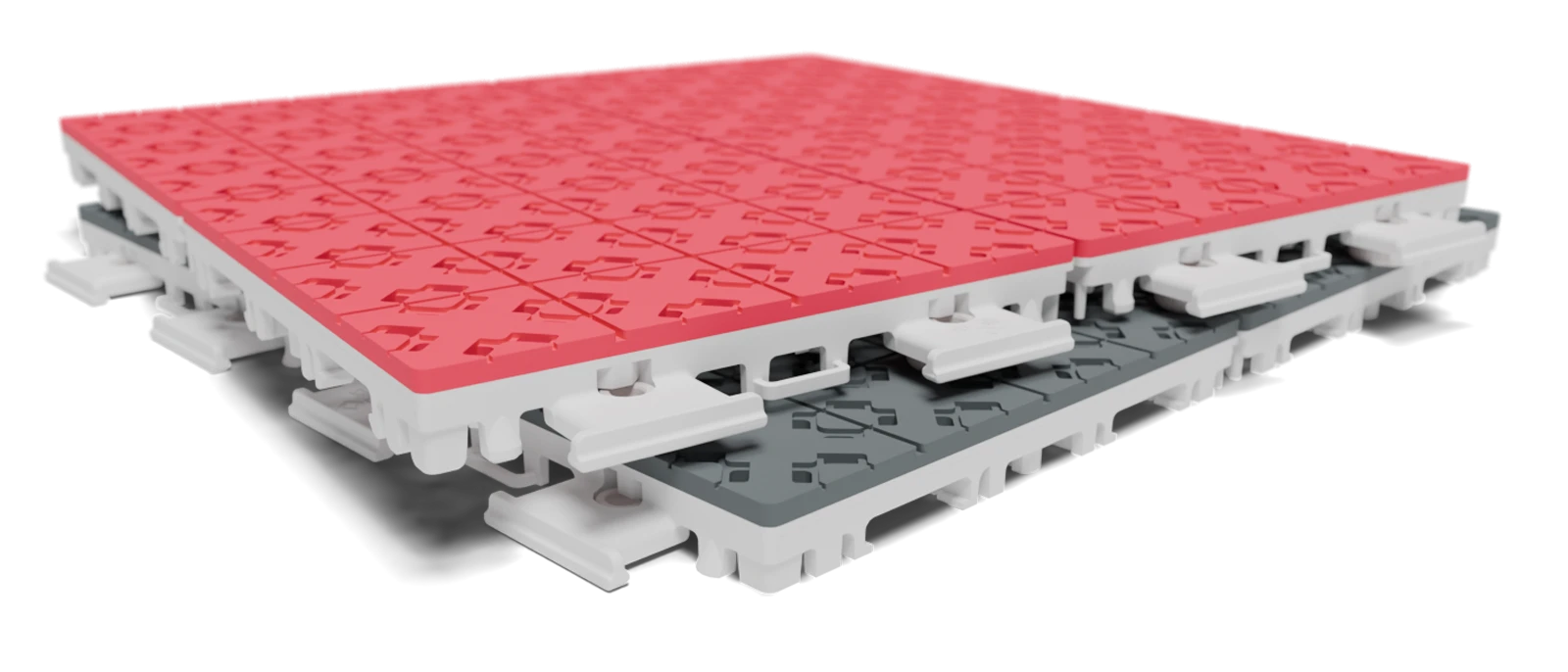

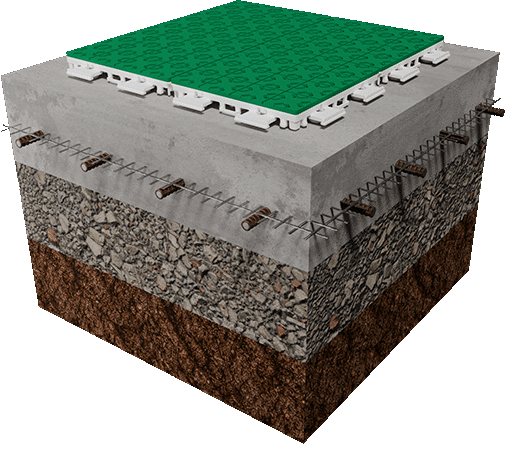

A maioria dos campos de basquetebol é construída sobre betão ou asfalto, sendo o betão a solução preferida na maioria das instalações. Proporciona uma base estável e previsível que garante ressalto consistente da bola e desempenho duradouro da superfície.

Para campos de basquetebol, uma laje de betão armado deve normalmente cumprir os seguintes critérios:

- Espessura mínima de 100–150 mm

- Armadura com malha de aço ou varões de reforço

- Acabamento nivelado a laser

- Svak helning for utendørs drenering

As bases em asfalto podem ser adequadas em determinadas situações, mas exigem uma preparação mais rigorosa e estão mais sujeitas a movimentos a longo prazo.

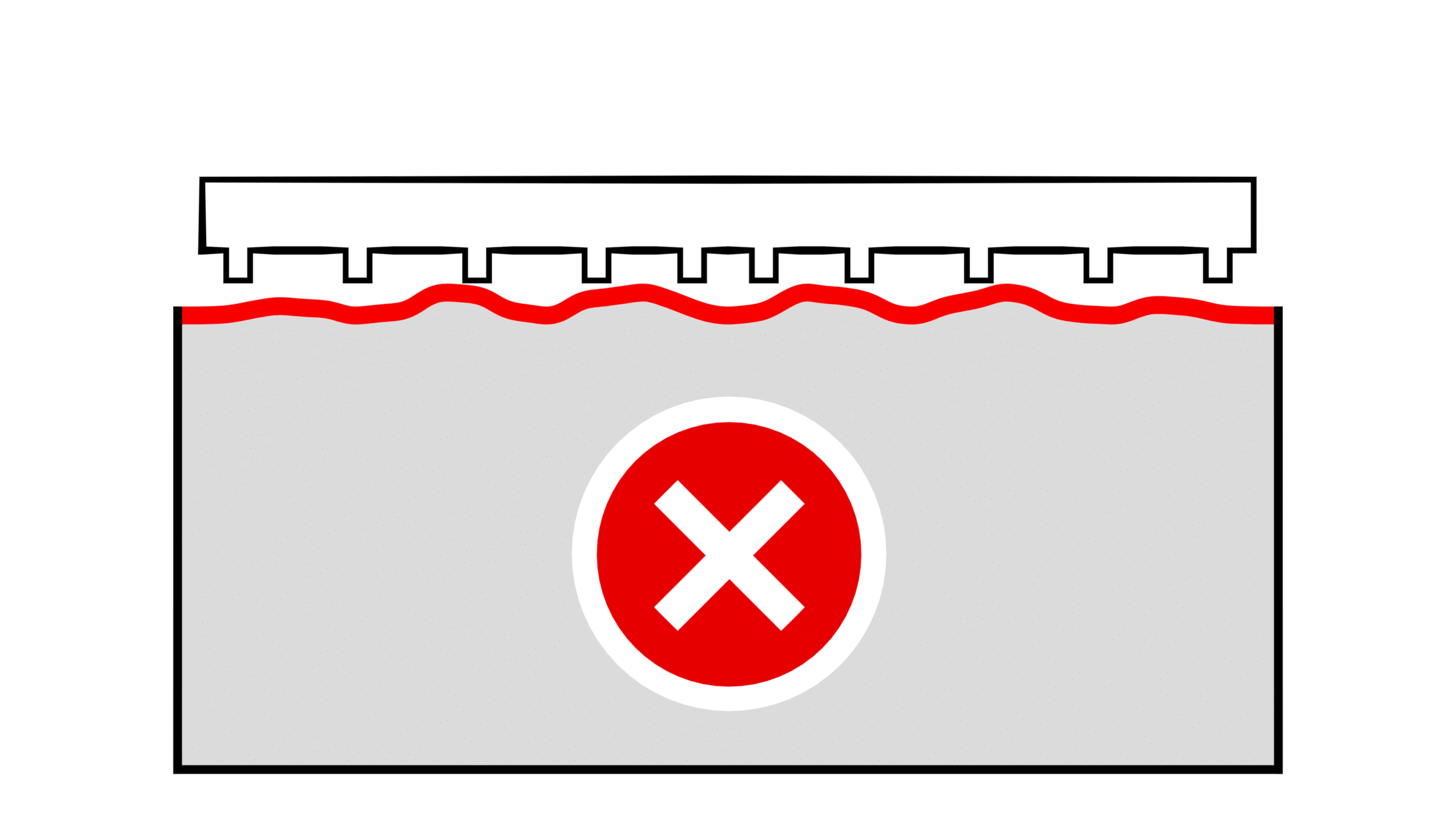

Requisitos de planicidade e tolerâncias

A superfície de um campo de basquetebol é implacável quando se trata de fundações irregulares. Ao contrário de pavimentos ou de obras duras em geral, a superfície de jogo amplifica as imperfeições em vez de as esconder. Mesmo pequenas variações na sub-base podem afetar o ressalto da bola, criar apoio desconfortável e dificultar a instalação da superfície.

Por este motivo, os campos de basquetebol exigem um padrão de planicidade mais elevado do que a maioria das lajes exteriores. O objetivo não é a perfeição visual, mas um desempenho consistente em toda a área de jogo. Como orientação prática, a sub-base de um campo de basquetebol deve cumprir as seguintes tolerâncias:

- Desvio não superior a 3–5 mm em 3 metros

- Sem mudanças bruscas de nível ou ressaltos

- Sem água acumulada após a chuva (para campos exteriores)

Cumprir estas tolerâncias na fase da sub-base evita problemas que são difíceis ou impossíveis de corrigir após a instalação da superfície.

Drenagem e preparação do terreno

Para campos exteriores, a drenagem é tão importante quanto a planicidade. A água que não consegue escoar acabará por causar movimentos, fissuras ou danos por gelo.

Uma boa preparação do terreno envolve normalmente uma camada compactada de pedra ou tout-venant sob a laje, combinada com uma inclinação suave que conduz a água para fora da área do campo. O objetivo não é criar uma inclinação visível, mas evitar a formação de água parada na superfície.

Ignorar a drenagem raramente causa uma falha imediata — provoca problemas lentos e dispendiosos mais tarde.

Verificação da prontidão da sub-base

Antes de avançar para a instalação da superfície do campo de basquetebol, faça uma pausa e confirme o seguinte. Se conseguir assinalar cada ponto com confiança, a sub-base está pronta.

A sua sub-base deve ser:

- Estruturalmente sólida, totalmente curada e sem fissuras

- Plana dentro das tolerâncias de um campo de basquetebol (sem depressões ou ressaltos visíveis)

- Seca, limpa e livre de detritos

- Corretamente drenada, sem água acumulada após a chuva

- Construída com as dimensões e a orientação corretas para o layout do campo

Se algum destes pontos for incerto, resolva-o antes de instalar a superfície. Corrigir problemas nesta fase é simples. Mais tarde, não é.

A OnCourt fornece desenhos técnicos e orientações de tolerância para empreiteiros que constroem sub-bases de campos.

Erros comuns a evitar

A maioria dos problemas da sub-base resulta de atalhos, e não de más intenções. Utilizar tolerâncias de pátio, omitir armaduras, betonagem sem controlo preciso de nível ou acelerar o processo de cura são erros que comprometem o campo antes mesmo de estar construído.

- Utilização de tolerâncias inadequadas

- Sem armadura

- Betonagem sem controlo de nível

- Instalação antes da cura completa

O princípio fundamental é simples: corrigir problemas da sub-base após a instalação é muito mais difícil do que construí-la corretamente desde o início.

Quando a sub-base está pronta?

Antes de avançar para a instalação da superfície, a sub-base deve estar totalmente curada, limpa e estruturalmente sólida. Deve cumprir as tolerâncias de planeza e não apresentar sinais de fissuras, movimentos ou zonas moles.

Quando estas condições são cumpridas, a instalação da superfície do campo e do cesto torna-se simples.

Quem deve construir a sub-base?

Embora muitas superfícies de campos de basquetebol possam ser instaladas em regime DIY, a construção da sub-base é melhor realizada por profissionais experientes em trabalhos de terraplanagem. Esta fase exige o equipamento adequado, conhecimento das condições locais do solo e compreensão de requisitos de tolerância que vão além do paisagismo geral.

A OnCourt fornece desenhos técnicos e especificações para que os empreiteiros locais possam construir a base corretamente, sem suposições. Esta abordagem combina a experiência local com padrões de desempenho claros.

Perguntas frequentes sobre a sub-base de campos de basquetebol

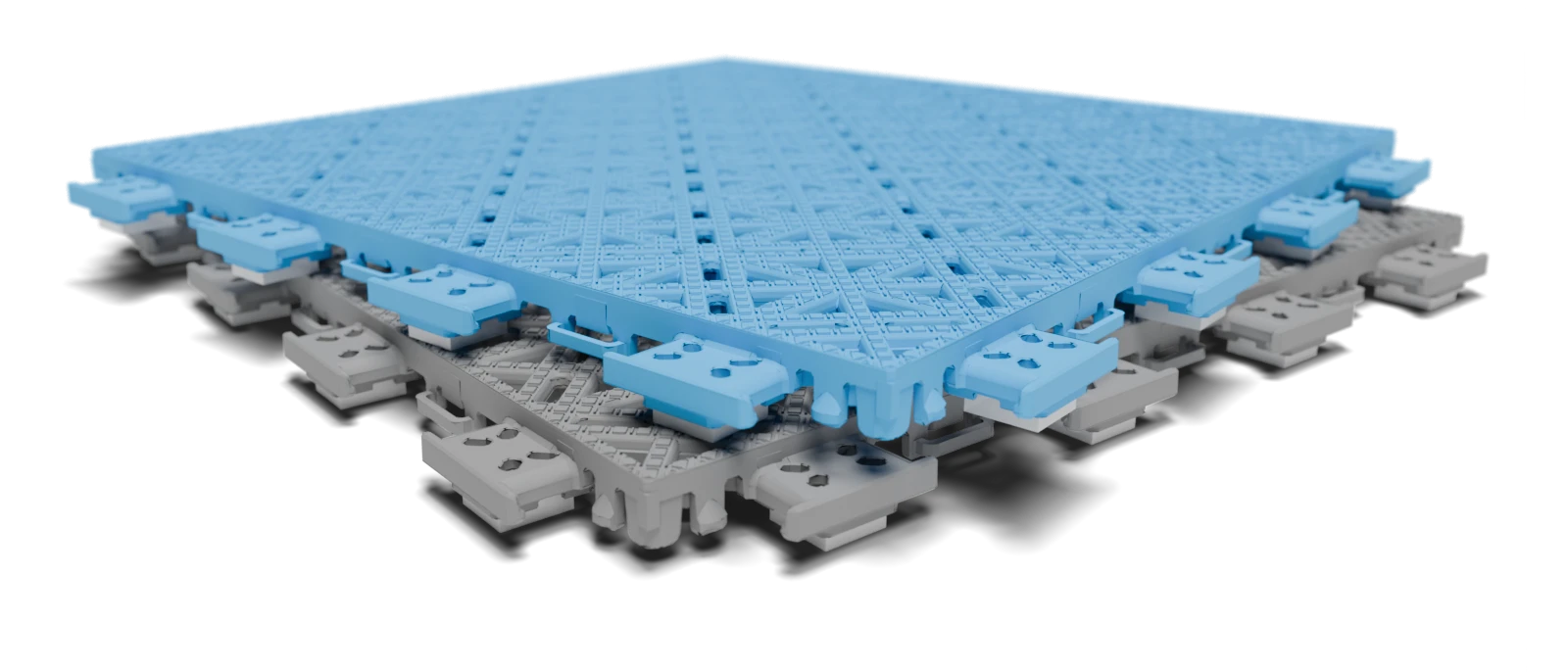

A sub-base é a camada compactada de fundação sob a superfície da quadra. Ela dá suporte ao sistema de placas modulares, absorve carga, evita movimentações e garante um quique consistente da bola. Sem uma sub-base sólida, a quadra pode se deslocar, ter áreas com mau desempenho ou apresentar problemas de drenagem com o tempo.

A profundidade da escavação depende do substrato, das condições do solo e do clima, mas normalmente varia entre 100 mm e 250 mm. Em solos moles ou climas frios, pode ser necessário cavar mais fundo para evitar levantamento por gelo e afundamentos.

Uma sub-base comum inclui:

– Brita Tipo 1 MOT para compactação e drenagem.

– Uma camada de areia grossa compactada ou uma camada fina niveladora.

– Opcionalmente, manta geotêxtil para controle de ervas daninhas e estabilidade.

Para melhores resultados, finalize com uma base de concreto ou asfalto bem nivelada ao instalar pisos modulares. Como mencionado neste artigo, uma tolerância de planicidade de no máximo 5 mm em um raio de 3 m garantirá ótimo desempenho.

A sub-base deve estar nivelada com uma tolerância máxima de 5 mm em qualquer raio de 3 m. Esta tolerância é fundamental para que as placas modulares se encaixem corretamente e proporcionem uma experiência de jogo segura e uniforme.

Sim. A drenagem adequada é essencial para evitar o acúmulo de água sob a superfície modular. Inclua uma leve inclinação, camadas de base permeáveis ou canais de drenagem conforme necessário em quadras externas.

Sim, se tiver confiança em escavação e compactação. Muitos fazem a sub-base por conta própria, mas para campos maiores ou mais complexos, recomendamos contratar um empreiteiro profissional.

Trabalhar com um empreiteiro local é geralmente a escolha mais sensata. Eles estão mais preparados para avaliar as condições do solo, lidar com desafios de drenagem regionais e mobilizar os equipamentos e materiais adequados com mais eficiência. Uma sub-base bem feita garante que o campo tenha um desempenho ideal por muitos anos.

Instalar o Mega Slam Hoop “in-ground” é um trabalho em duas etapas. Primeiro, cava-se um buraco de 1,25 m de profundidade para o ancoramento em concreto. Depois vem a montagem do sistema. Os aros Mega Slam são pesados – é isso que os torna os melhores para uso doméstico. Vai precisar da ajuda de amigos para levantar. Saiba mais sobre a Instalação de Mega Slam Hoops.

NOTA - Os ancoramentos do sistema e dos componentes devem ser instalados durante a construção da sub-base. Configure e encomende a quadra, o aro e os acessórios com antecedência para garantir que os ancoramentos estejam prontos a tempo.

Próximos passos

Com a sub-base concluída, está pronto para passar dos trabalhos de terraplanagem para a montagem do campo.