Grunnlaget for en langvarig basketballbane

En basketballbane er bare så god som underlaget under den. Lenge før flisene klikkes sammen eller kurven monteres, avgjør bærelaget hvordan banen vil fungere, hvor lenge den varer og om problemer oppstår etter måneder eller år.

Denne guiden fokuserer spesifikt på bygging av bærelaget for en basketballbane. Den dekker ikke installasjon av overflate eller montering av kurv — disse trinnene kommer senere. Et riktig utført fundament er det som gjør at alt annet fungerer som det skal.

Hva er bærelaget til en basketballbane?

Bærelaget er det konstruerte fundamentet som støtter spilleoverflaten. Oppgaven virker enkel: holde seg plant, stabilt og håndtere vann. I praksis innebærer dette å bære spillerbelastninger, motstå bevegelser i grunnen og forhindre at fukt skader banen over.

For basketballbaner, spesielt de med modulært dekke, må bærelaget være flatere og mer presist enn for en vanlig terrasse, innkjørsel eller hageheller. Små avvik som ville vært akseptable andre steder, kan føre til problemer på banen.

Valg av riktig type bærelag

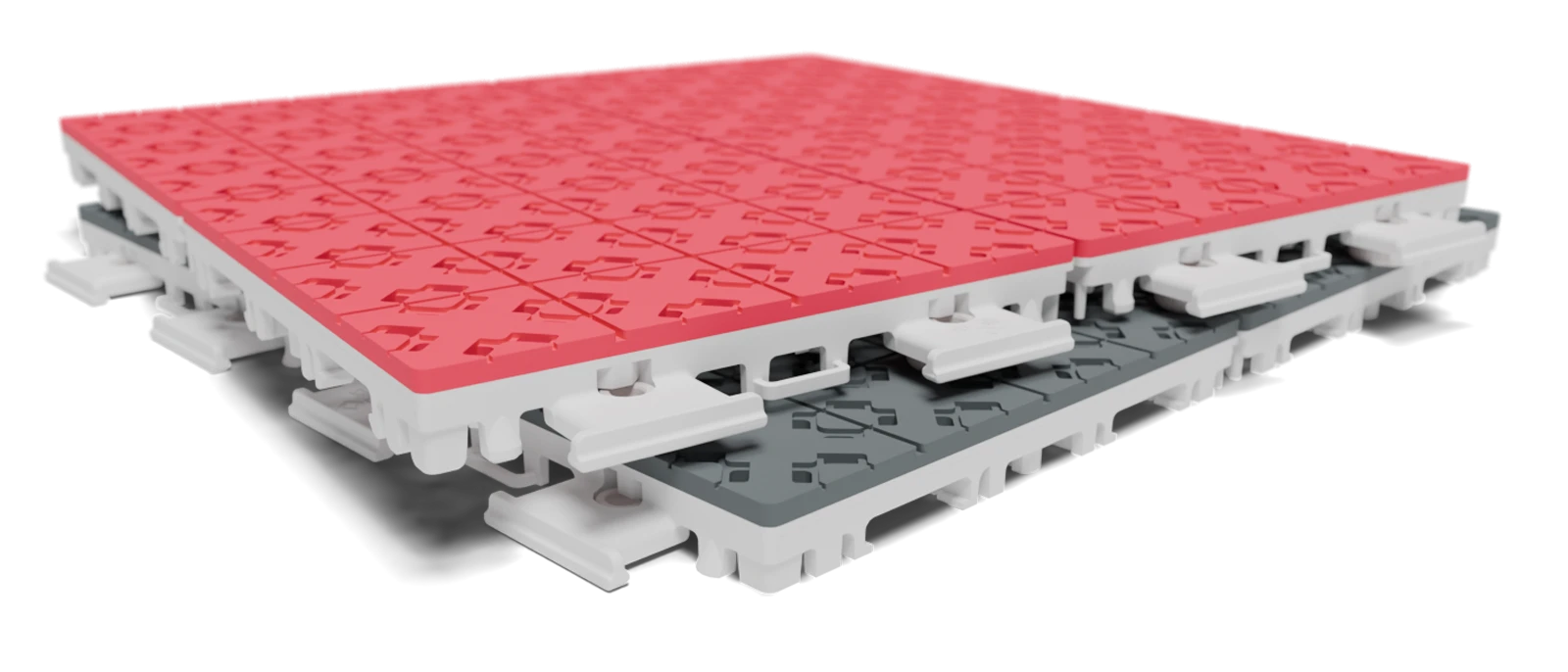

De fleste basketballbaner bygges enten på betong eller asfalt, der betong er den foretrukne løsningen i de fleste installasjoner. Den gir et stabilt og forutsigbart fundament som sikrer jevn ballsprett og langsiktig overflateytelse.

For basketballbaner bør en armert betongplate vanligvis oppfylle følgende kriterier:

- Minimalus storis 100–150 mm

- Armering med stålnett eller armeringsjern

- Laseravrettet overflate

- Svak helning for utendørs drenering

Asfaltbaser kan være egnet i visse situasjoner, men de krever strengere forberedelse og er mer utsatt for langsiktige bevegelser.

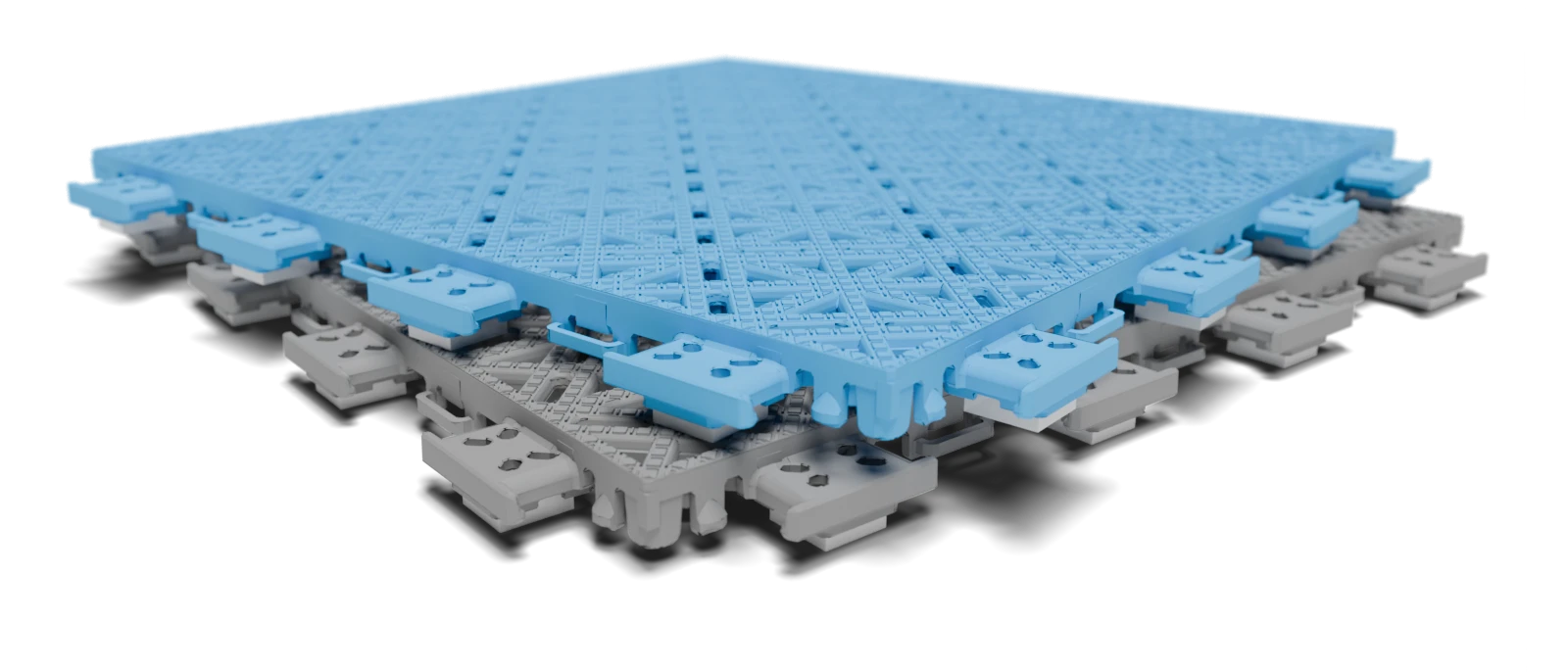

Krav til planhet og toleranser

En basketballbane er lite tilgivende når det gjelder ujevne fundamenter. I motsetning til belegning eller generell utebygging forsterker spilleoverflaten ujevnheter i stedet for å skjule dem. Selv små avvik i bærelaget kan påvirke ballsprett, gi ubehagelig fotfeste og gjøre installasjonen av overflaten mer krevende.

Av denne grunn krever basketballbaner en høyere planhetsstandard enn de fleste utendørs betongdekker. Målet er ikke visuell perfeksjon, men jevn ytelse over hele spilleflaten. Som en praktisk veiledning bør bærelaget til en basketballbane oppfylle følgende toleransekrav:

- Ikke mer enn 3–5 mm avvik over 3 meter

- Ingen brå nivåendringer eller kanter

- Ingen stående vann etter regn (for utendørsbaner)

Å oppfylle disse toleransene i bærelagsfasen forhindrer problemer som er vanskelige eller umulige å rette etter at overflaten er installert.

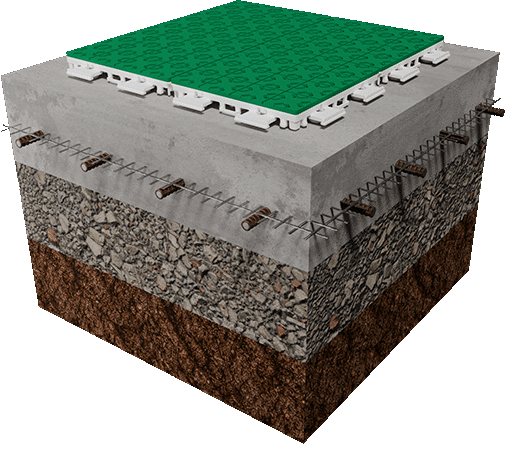

Drenering og grunnforberedelse

For utendørsbaner er drenering like viktig som planhet. Vann som ikke kan ledes bort vil over tid føre til bevegelser, sprekker eller frostskader.

God grunnforberedelse innebærer vanligvis et komprimert lag med stein eller bærelag under platen, kombinert med en svak helning som leder vann bort fra baneområdet. Målet er ikke å skape et synlig fall, men å forhindre at det blir stående vann på overflaten.

Å ignorere drenering fører sjelden til umiddelbar svikt — det skaper langsomme og kostbare problemer senere.

Kontroll av bærelagets klargjøring

Før du går videre med installasjonen av basketballbanens overflate, bør du stoppe opp og bekrefte følgende. Hvis du trygt kan krysse av hvert punkt, er bærelaget klart.

Bærelaget ditt bør være:

- Strukturelt stabil, fullstendig herdet og fri for sprekker

- Plan innenfor toleransene for basketballbaner (ingen synlige søkk eller kanter)

- Tørr, ren og fri for rusk

- Riktig drenert, uten stående vann etter regn

- Bygget med riktige dimensjoner og orientering for banens layout

Hvis noen av disse punktene er usikre, bør de avklares før overflaten installeres. Å rette problemer på dette stadiet er enkelt. Senere er det ikke.

OnCourt tilbyr tekniske tegninger og toleranseveiledning for entreprenører som bygger bærelag for baner.

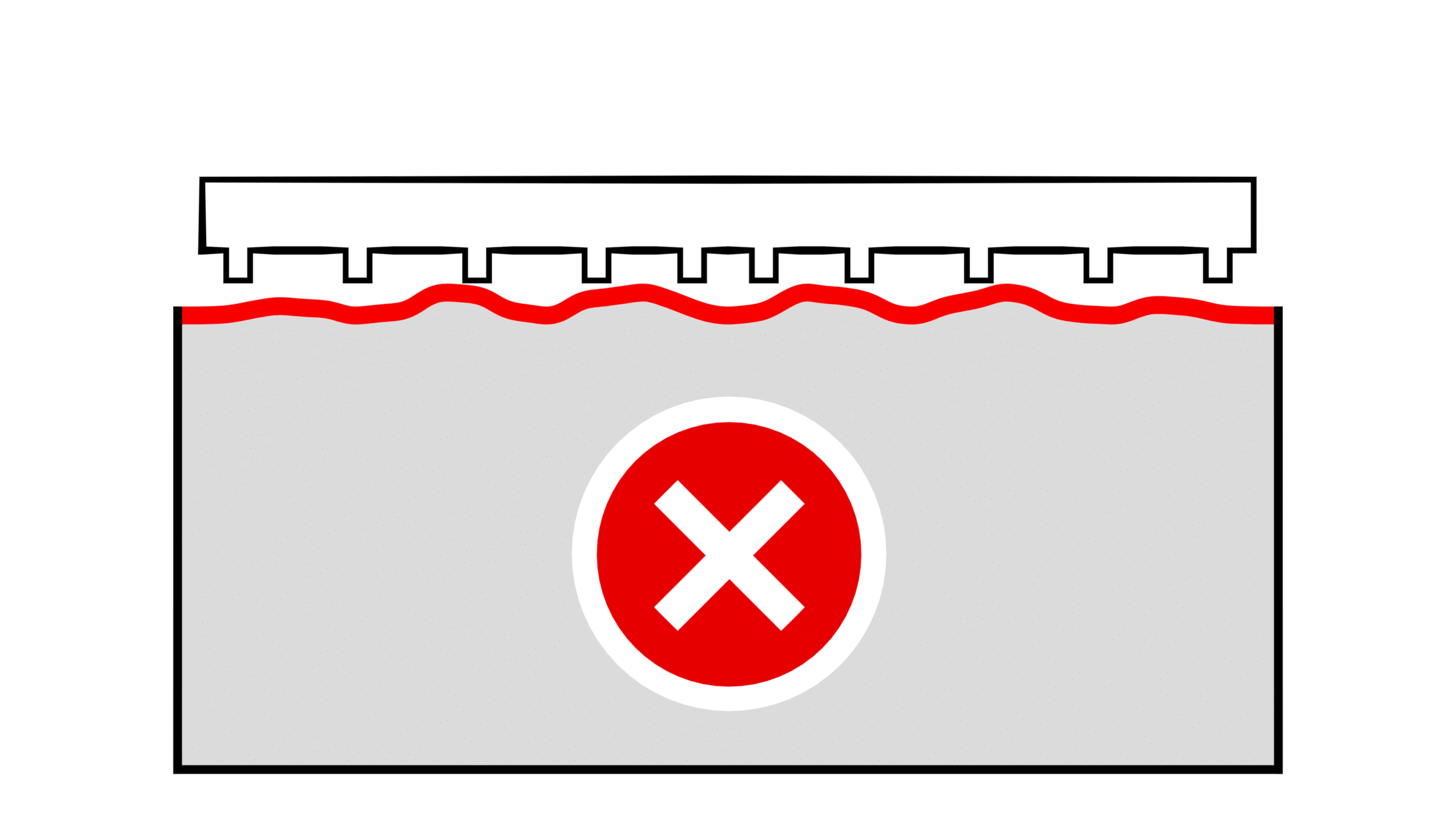

Vanlige feil som bør unngås

De fleste problemer med bærelaget skyldes snarveier, ikke dårlige hensikter. Bruk av terrassetoleranser, manglende armering, støping uten nøyaktig nivåkontroll eller for rask herding er feil som svekker banen før den i det hele tatt er ferdig bygget.

- Bruk av utilstrekkelige toleranser

- Uten armering

- Støping uten nivåkontroll

- Installasjon før full herding

Hovedprinsippet er enkelt: å rette problemer med bærelaget etter installasjon er langt vanskeligere enn å bygge det riktig fra starten av.

Når er bærelaget klart?

Før man går videre med installasjon av overflaten, skal bærelaget være fullstendig herdet, rent og strukturelt stabilt. Det må oppfylle planhetstoleranser og ikke vise tegn til sprekker, bevegelse eller myke områder.

Når disse forutsetningene er oppfylt, blir installasjonen av baneoverflaten og kurven enkel.

Hvem bør bygge bærelaget?

Selv om mange basketballbaneoverflater kan installeres på egen hånd, bør bygging av bærelaget håndteres av erfarne fagfolk innen grunnarbeid. Dette trinnet krever riktig utstyr, kunnskap om lokale grunnforhold og forståelse for toleransekrav som går utover vanlig landskapsarbeid.

OnCourt tilbyr tekniske tegninger og spesifikasjoner slik at lokale entreprenører kan bygge fundamentet korrekt uten gjetting. Denne tilnærmingen kombinerer lokal ekspertise med klare ytelsesstandarder.

FAQ om bærelag for basketballbaner

Underlaget er det komprimerte fundamentet under banens overflate. Det støtter det modulære flisesystemet, absorberer belastning, forhindrer bevegelse og sørger for jevn basketballsprett. Uten et solid underlag kan banen forskyve seg, få dødpunkter eller dårlig drenering over tid.

Gravedybden avhenger av underlag, grunnforhold og klima, men ligger vanligvis mellom 100 mm og 250 mm. Ved myk jord eller kaldt klima kan det være nødvendig å grave dypere for å unngå frostskader og setningsproblemer.

Et vanlig underlag inkluderer:

– Type 1 MOT (knust stein) for komprimering og drenering.

– Et lag komprimert, grov sand eller et tynt avrettingslag.

– Eventuelt geotekstil for ugresskontroll og stabilitet.

For best resultat, avslutt med en jevn betong- eller asfaltplate ved installasjon av modulbaserte fliser. Som nevnt i denne artikkelen vil en jevnhetstoleranse på maks 5 mm i en radius på 3 m sikre høy ytelse.

Underlaget må være jevnt innenfor en toleranse på 5 mm i en radius på 3 m. Denne toleransen er avgjørende for at modulflisene skal låses godt og gi en trygg og jevn spilleopplevelse.

Ja. Riktig drenering er viktig for å forhindre vannansamling under den modulære baneflaten. Inkluder svak helning, gjennomtrengelige lag eller dreneringskanaler ved behov på utendørsbaner.

Ja, hvis du er trygg på graving og komprimering. Mange gjør det selv, men for større eller mer komplekse baner anbefaler vi å bruke en profesjonell entreprenør.

En lokal grunnentreprenør er ofte det smarteste valget. De har bedre kjennskap til lokale grunnforhold, dreneringsutfordringer og kan raskt mobilisere riktig utstyr og materialer. Et profesjonelt forberedt underlag sikrer at banen din yter optimalt i mange år.

Å installere en Mega Slam Hoop i bakken er en jobb i to trinn. Først graves det et 1,25 m dypt hull for betongfundamentet. Deretter monteres selve kurven. Mega Slam-kurver er tunge – det er det som gjør dem best for hjemmebruk. Du trenger hjelp til løftingen. Les mer om Installasjon av Mega Slam Hoops.

MERK - Ankerfester for kurv og komponenter bør installeres under bygging av underlaget. Konfigurer og bestill bane, kurv og tilbehør på forhånd for å sikre at alt er klart under grunnarbeidet.

Neste steg

Når bærelaget er ferdig, er du klar til å gå fra grunnarbeid til montering av banen.