La base de una cancha de baloncesto duradera

Una cancha de baloncesto es tan buena como la superficie que la sostiene. Mucho antes de que se encajen las losetas o se instale la canasta, la subbase determina cómo se comportará la cancha, cuánto durará y si surgirán problemas meses o años después.

Esta guía se centra específicamente en la construcción de la subbase para una cancha de baloncesto. No cubre la instalación de la superficie ni el montaje de la canasta — esos pasos vienen después. Hacer bien la base es lo que permite que todo lo demás funcione correctamente.

¿Qué es la subbase de una cancha de baloncesto?

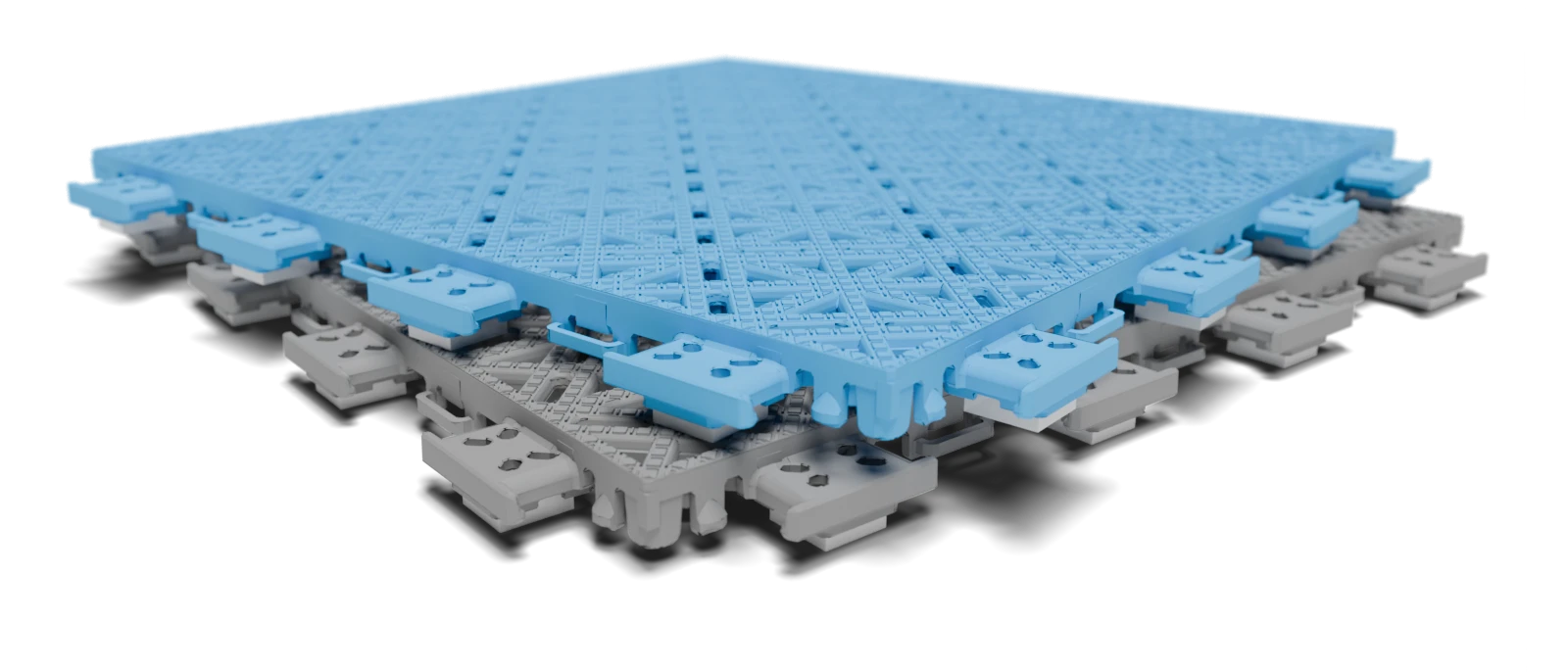

La subbase es la base estructural diseñada que soporta la superficie de juego. Su función parece sencilla: mantenerse plana, estable y gestionar el agua. En la práctica, esto implica soportar las cargas de los jugadores, resistir los movimientos del terreno y evitar que la humedad dañe la cancha superior.

En las canchas de baloncesto, especialmente aquellas con pavimento modular, la subbase debe ser más plana y precisa que la de un patio, entrada para vehículos o losa de jardín convencional. Pequeñas desviaciones que serían aceptables en otros contextos pueden causar problemas en una cancha.

Elegir el tipo de subbase adecuado

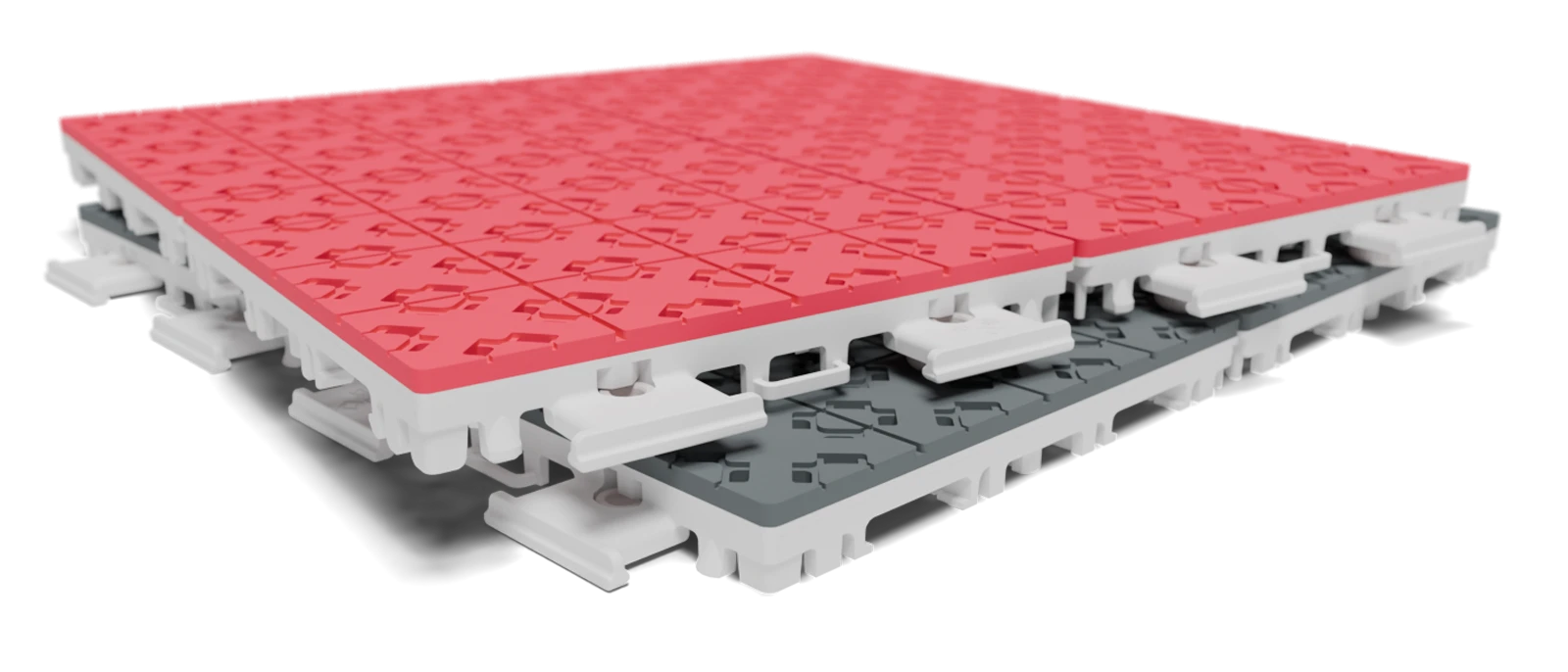

La mayoría de las canchas de baloncesto se construyen sobre hormigón o asfalto, siendo el hormigón la solución preferida en la mayoría de las instalaciones. Proporciona una base estable y predecible que favorece un bote constante del balón y un rendimiento duradero de la superficie.

En las canchas de baloncesto, una losa de hormigón armado debería cumplir normalmente los siguientes criterios:

- Espesor mínimo de 100–150 mm

- Refuerzo con malla de acero o barras de refuerzo

- Acabado nivelado por láser

- Pendiente suave para drenaje exterior

Las bases de asfalto pueden ser adecuadas en determinadas situaciones, pero requieren una preparación más estricta y son más propensas a movimientos a largo plazo.

Requisitos de planicidad y tolerancias

La superficie de una cancha de baloncesto no perdona las bases irregulares. A diferencia del pavimento o de la obra dura general, la superficie de juego amplifica las imperfecciones en lugar de ocultarlas. Incluso pequeñas desviaciones en la subbase pueden afectar el bote del balón, generar una pisada incómoda y dificultar la instalación de la superficie.

Por este motivo, las canchas de baloncesto requieren un estándar de planicidad más alto que la mayoría de las losas exteriores. El objetivo no es la perfección visual, sino un rendimiento uniforme en toda la superficie de juego. Como guía práctica, la subbase de una cancha de baloncesto debe cumplir las siguientes tolerancias:

- No más de 3–5 mm de desviación en 3 metros

- Sin cambios bruscos de nivel ni crestas

- Sin agua estancada tras la lluvia (para canchas exteriores)

Cumplir estas tolerancias en la fase de subbase evita problemas que son difíciles o imposibles de corregir una vez instalada la superficie de juego.

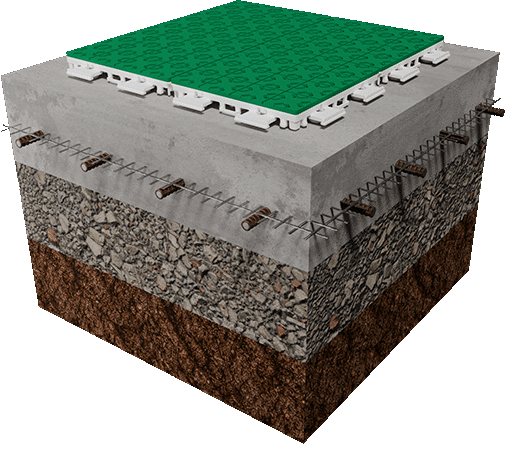

Drenaje y preparación del terreno

En las canchas exteriores, el drenaje es tan importante como la planicidad. El agua que no puede evacuarse acabará provocando movimientos, grietas o daños por heladas.

Una buena preparación del terreno suele implicar una capa compactada de piedra o zahorra bajo la losa, combinada con una pendiente suave que conduzca el agua fuera del área de juego. El objetivo no es crear una pendiente visible, sino evitar la formación de agua estancada en la superficie.

Ignorar el drenaje rara vez provoca un fallo inmediato; en cambio, genera problemas lentos y costosos con el tiempo.

Comprobación de la preparación de la subbase

Antes de continuar con la instalación de la superficie de la cancha de baloncesto, deténgase y confirme lo siguiente. Si puede marcar cada punto con seguridad, la subbase está lista.

Su subbase debe ser:

- Estructuralmente sólida, completamente curada y sin grietas

- Plana dentro de las tolerancias de una cancha de baloncesto (sin hundimientos ni crestas visibles)

- Seca, limpia y libre de residuos

- Correctamente drenada, sin agua estancada tras la lluvia

- Construida con las dimensiones y la orientación correctas para el diseño de la cancha

Si alguno de estos puntos no está claro, resuélvalo antes de instalar la superficie. Corregir problemas en esta fase es sencillo. Más adelante no lo es.

OnCourt proporciona planos técnicos y directrices de tolerancia para contratistas que construyen subbases de canchas.

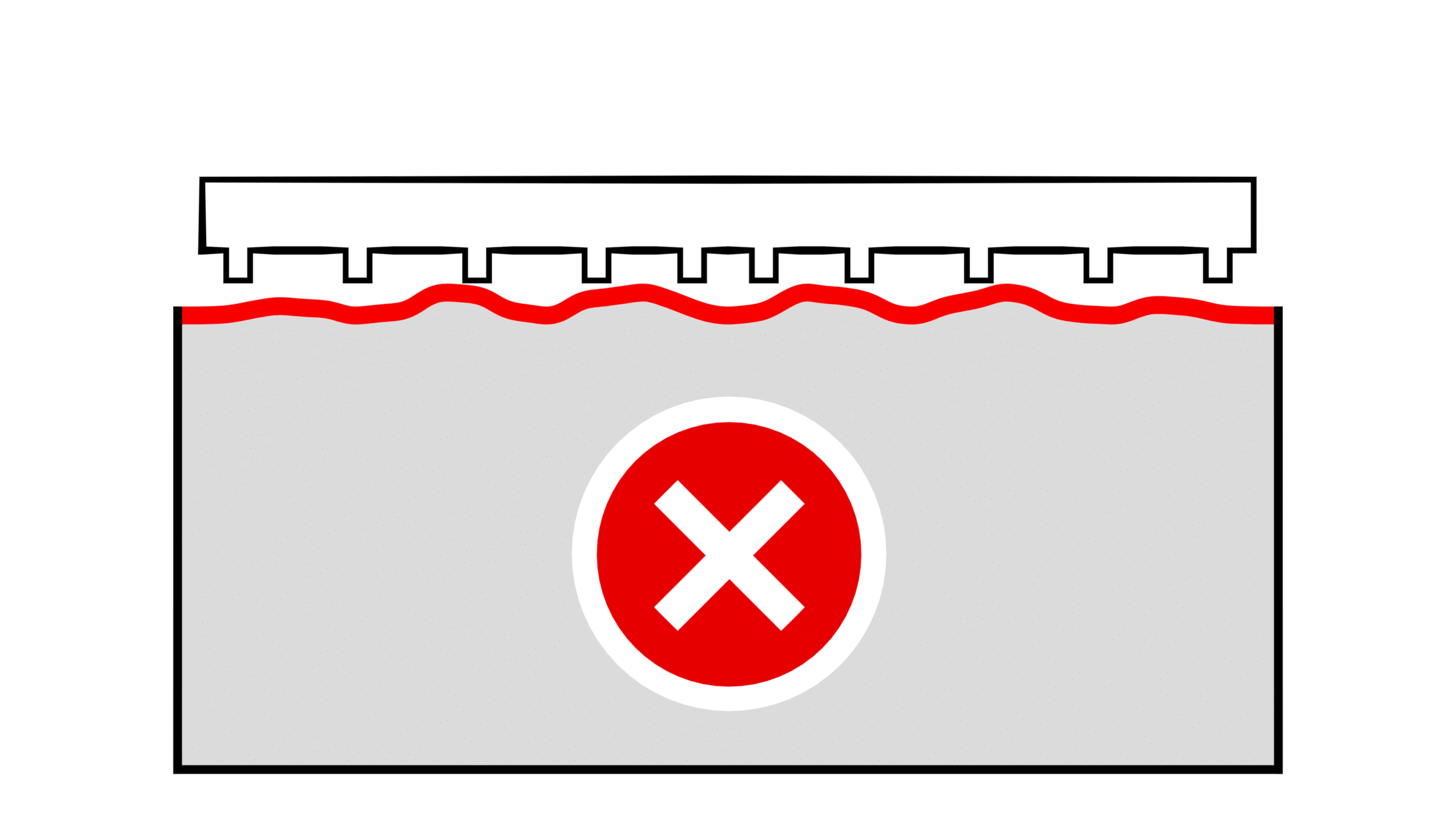

Errores comunes que se deben evitar

La mayoría de los problemas de la subbase se deben a atajos, no a malas intenciones. Utilizar tolerancias propias de patios, omitir la armadura, verter sin un control preciso del nivel o apresurar el curado son errores que comprometen la cancha incluso antes de que esté construida.

- Uso de tolerancias deficientes

- Sin refuerzo

- Vertido sin control de nivel

- Instalación antes del curado completo

El principio clave es sencillo: corregir problemas de la subbase después de la instalación es mucho más difícil que construirla correctamente desde el principio.

¿Cuándo está lista la subbase?

Antes de continuar con la instalación de la superficie, la subbase debe estar completamente curada, limpia y estructuralmente sólida. Debe cumplir con las tolerancias de planitud y no mostrar signos de grietas, movimiento ni zonas blandas.

Una vez cumplidas estas condiciones, la instalación de la superficie de la cancha y la canasta resulta sencilla.

¿Quién debe construir la subbase?

Aunque muchas superficies de canchas de baloncesto pueden instalarse por cuenta propia, la construcción de la subbase se deja mejor en manos de profesionales experimentados en trabajos de movimiento de tierras. Esta etapa requiere el equipo adecuado, conocimiento de las condiciones del terreno local y una comprensión de los requisitos de tolerancia que van más allá del paisajismo general.

OnCourt proporciona planos técnicos y especificaciones para que los contratistas locales puedan construir la base correctamente sin conjeturas. Este enfoque combina la experiencia local con estándares de rendimiento claros.

Preguntas frecuentes sobre la subbase de canchas de baloncesto

La subbase es la capa de cimentación compactada debajo de la superficie de la cancha. Soporta el sistema de losetas modulares, absorbe cargas, evita desplazamientos y garantiza un rebote constante del balón. Sin una subbase sólida, la cancha puede desplazarse, tener zonas muertas o drenaje deficiente con el tiempo.

La profundidad de excavación depende del sustrato, las condiciones del suelo y el clima, pero normalmente varía entre 100 mm y 250 mm. En suelos blandos o climas fríos, puede ser necesario excavar más profundo para evitar levantamientos por congelación y hundimientos.

Una subbase típica incluye:

– Piedra triturada tipo 1 MOT para compactación y drenaje.

– Una capa de arena gruesa compactada o una capa fina de acabado.

– Opcionalmente, tela geotextil para control de malezas y estabilidad.

Para mejores resultados, finaliza con una losa de hormigón o asfalto nivelada al instalar baldosas modulares. Como se menciona en este artículo, una tolerancia de planitud de no más de 5 mm en un radio de 3 m garantiza un rendimiento óptimo.

La subbase debe estar nivelada con una tolerancia de no más de 5 mm en un radio de 3 m. Esta precisión es fundamental para que las losetas modulares encajen correctamente y proporcionen una experiencia de juego segura y uniforme.

Sí. Un buen sistema de drenaje es fundamental para evitar acumulaciones de agua bajo la superficie modular. Incluye una pendiente suave, capas de base permeables o canales de drenaje para canchas al aire libre.

Sí, si tienes confianza en trabajos de excavación y compactación. Muchos aficionados construyen su propia subbase, pero para canchas más grandes o complejas, recomendamos contratar a un profesional.

Trabajar con un contratista local de obras es a menudo la opción más inteligente. Están mejor equipados para evaluar las condiciones del suelo, entender los desafíos locales de drenaje y movilizar maquinaria y materiales adecuados de forma más eficiente. Una subbase bien preparada garantiza que tu pista funcione al máximo nivel durante muchos años.

La instalación del aro Mega Slam empotrado se realiza en dos etapas. Se excava un hoyo de 1,25 m de profundidad para el anclaje de concreto. Después, se monta el sistema del aro. Los Mega Slam Hoops son pesados – es lo que los convierte en el mejor aro doméstico. Por eso necesitarás ayuda para levantarlo. Más información sobre la Instalación de Mega Slam Hoops.

NOTA - Los anclajes del sistema y los componentes deben instalarse durante la construcción de la subbase. Configura y haz el pedido de tu cancha, aro y accesorios con antelación para que estén disponibles a tiempo.

Siguientes pasos

Con la subbase terminada, ya puede pasar de los trabajos de cimentación al montaje de la cancha.