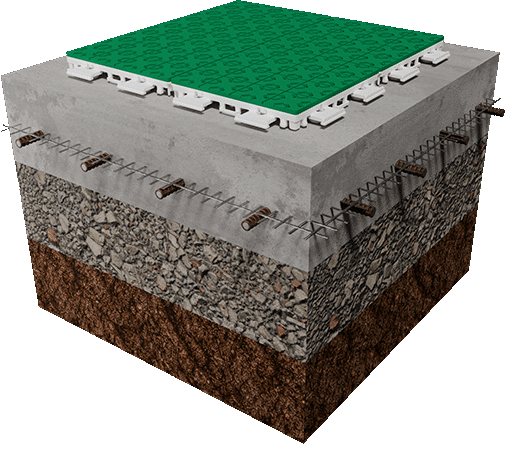

Ilgmūžīga basketbola laukuma pamats

Basketbola laukums ir tik labs, cik laba ir pamatne zem tā. Vēl ilgi pirms flīžu savienošanas vai groza uzstādīšanas pamatkārta nosaka, kā laukums darbosies, cik ilgi tas kalpos un vai problēmas parādīsies pēc mēnešiem vai gadiem.

Šis ceļvedis ir vērsts tieši uz basketbola laukuma pamatnes izbūvi. Tas neaptver seguma uzstādīšanu vai groza montāžu — šie posmi seko vēlāk. Pareizi izveidota pamatne nodrošina, ka viss pārējais darbojas korekti.

Kas ir basketbola laukuma pamatne?

Pamatkārta ir inženiertehniski izstrādāts pamats, kas balsta spēles segumu. Tās uzdevums šķiet vienkāršs: saglabāt līdzenumu, stabilitāti un pārvaldīt ūdeni. Praksē tas nozīmē spēlētāju slodžu uzņemšanu, pretestību grunts kustībām un mitruma radītu bojājumu novēršanu laukuma virspusē.

Basketbola laukumiem, īpaši tiem ar modulāro segumu, pamatnei jābūt līdzenākai un precīzākai nekā parastai terasei, piebraucamajam ceļam vai dārza plāksnei. Nelielas novirzes, kas citur būtu pieņemamas, var radīt problēmas laukumā.

Pareizā pamatnes veida izvēle

Lielākā daļa basketbola laukumu tiek būvēti uz betona vai asfalta, un betonam ir priekšroka lielākajā daļā uzstādījumu. Tas nodrošina stabilu un paredzamu pamatu, kas veicina vienmērīgu bumbas atlēcienu un ilgtermiņa seguma veiktspēju.

Basketbola laukumiem armētai betona plātnei parasti jāatbilst šādiem kritērijiem:

- Minimālais biezums 100–150 mm

- Pastiprinājums ar tērauda sietu vai armatūras stieņiem

- Ar lāzeru izlīdzināta apdare

- Neliels slīpums āra drenāžai

Asfalta pamatnes noteiktās situācijās var būt piemērotas, taču tām nepieciešama stingrāka sagatavošana un tās ir vairāk pakļautas ilgtermiņa kustībām.

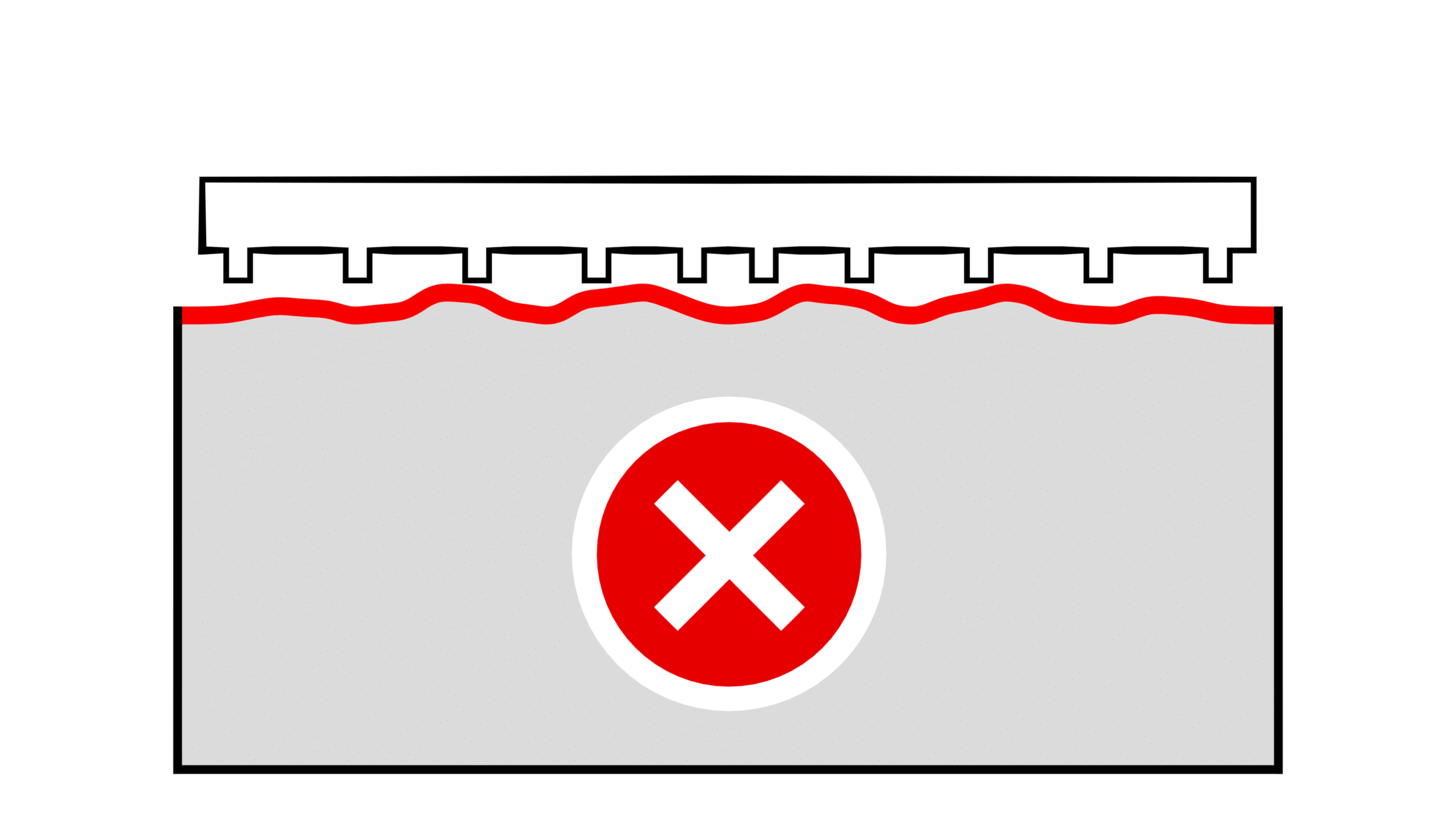

Līdzenuma un pielaižu prasības

Basketbola laukuma segums ir nepielūdzams attiecībā uz nelīdzenām pamatnēm. Atšķirībā no bruģa vai vispārējiem cietajiem segumiem, spēles virsma izceļ nepilnības, nevis tās slēpj. Pat nelielas novirzes pamatnē var ietekmēt bumbas atlēcienu, radīt neērtu balstu un apgrūtināt seguma uzstādīšanu.

Šī iemesla dēļ basketbola laukumiem ir nepieciešams augstāks līdzenuma standarts nekā lielākajai daļai āra plātņu. Mērķis nav vizuāla pilnība, bet gan vienmērīga veiktspēja visā spēles laukumā. Kā praktisks orientieris basketbola laukuma pamatnei jāatbilst šādām pielaižu prasībām:

- Novirze ne lielāka par 3–5 mm uz 3 metriem

- Bez straujām līmeņa izmaiņām vai izvirzījumiem

- Pēc lietus nedrīkst palikt stāvošs ūdens (āra laukumiem)

Šo pielaižu ievērošana pamatnes posmā novērš problēmas, kuras pēc seguma uzstādīšanas ir grūti vai neiespējami labot.

Drenāža un grunts sagatavošana

Āra laukumiem drenāža ir tikpat svarīga kā līdzenums. Ūdens, kas nevar aizplūst, laika gaitā izraisīs kustības, plaisas vai sala radītus bojājumus.

Laba grunts sagatavošana parasti ietver sablīvētu šķembu vai akmeņu slāni zem plātnes, apvienotu ar nelielu slīpumu, kas novada ūdeni prom no laukuma zonas. Mērķis nav radīt redzamu slīpumu, bet novērst stāvoša ūdens veidošanos uz virsmas.

Drenāžas ignorēšana reti izraisa tūlītēju bojājumu, taču vēlāk rada lēnas un dārgas problēmas.

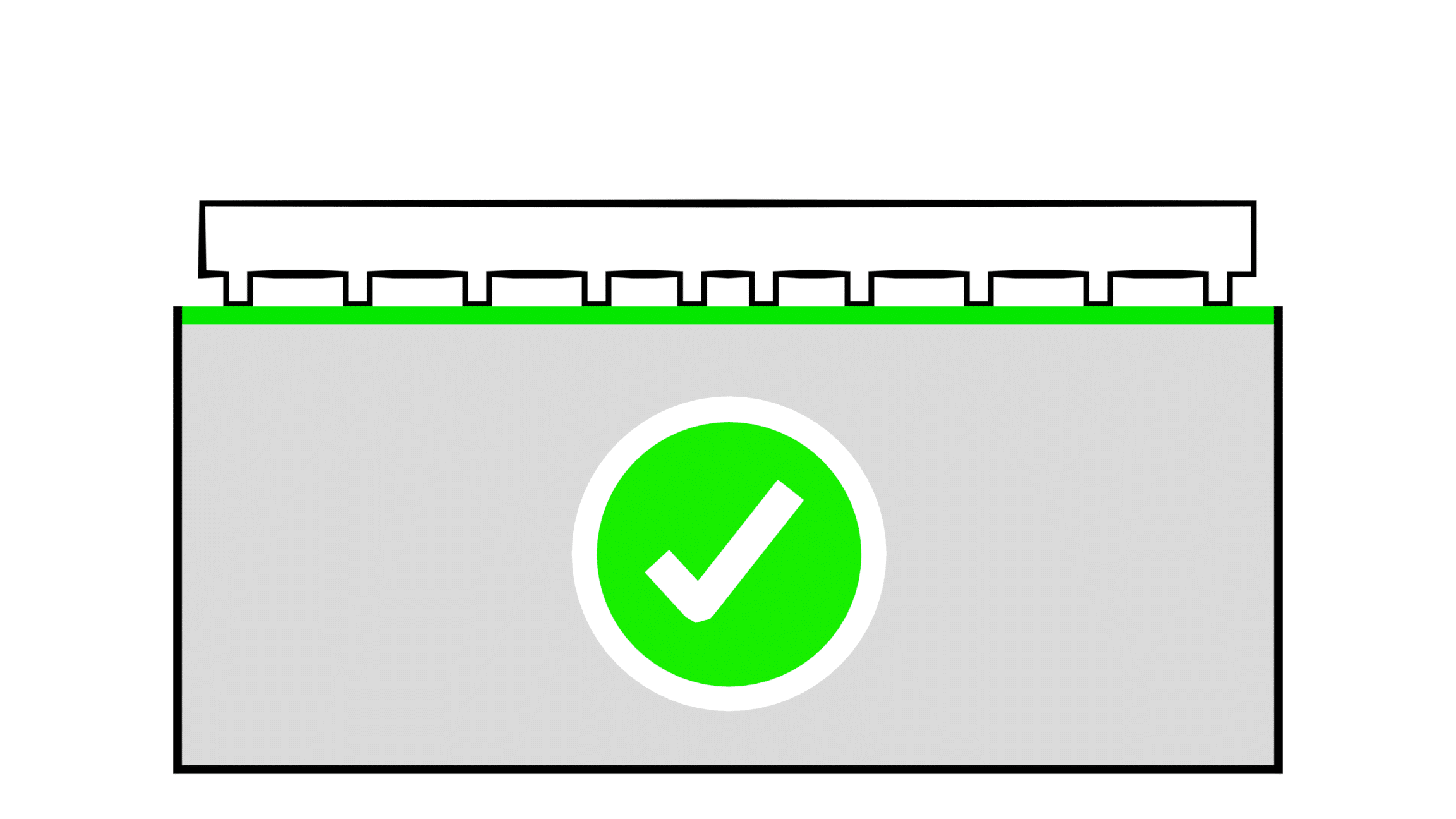

Pamatnes gatavības pārbaude

Pirms turpināt basketbola laukuma seguma uzstādīšanu, apstājieties un pārbaudiet sekojošo. Ja varat pārliecinoši atzīmēt katru punktu, pamatne ir gatava.

Jūsu pamatnei jābūt:

- Konstrukcionāli stabila, pilnībā sacietējusi un bez plaisām

- Līdzena basketbola laukuma pielaižu robežās (bez redzamiem iegrimumiem vai izvirzījumiem)

- Sausa, tīra un bez gružiem

- Pareizi drenēta, bez stāvoša ūdens pēc lietus

- Izbūvēta ar pareiziem izmēriem un orientāciju laukuma izkārtojumam

Ja kāds no šiem punktiem ir neskaidrs, novērsiet to pirms seguma uzstādīšanas. Šajā posmā problēmu novēršana ir vienkārša. Vēlāk — nē.

OnCourt nodrošina tehniskos rasējumus un pielaižu vadlīnijas būvniekiem, kas izbūvē laukumu pamatnes.

Biežāk pieļautās kļūdas, no kurām jāizvairās

Lielākā daļa pamatnes problēmu rodas saīsinātu risinājumu dēļ, nevis sliktu nodomu dēļ. Terases līmeņa pielaižu izmantošana, armējuma izlaišana, liešana bez precīzas līmeņa kontroles vai sacietēšanas procesa sasteigšana ir kļūdas, kas bojā laukumu vēl pirms tā izbūves.

- Nepietiekamu pielaižu izmantošana

- Bez armējuma

- Liešana bez līmeņa kontroles

- Uzstādīšana pirms pilnīgas sacietēšanas

Galvenais princips ir vienkāršs: pamatnes problēmu novēršana pēc uzstādīšanas ir daudz sarežģītāka nekā tās pareiza izbūve jau sākumā.

Kad pamatne ir gatava?

Pirms pāriet pie seguma uzstādīšanas pamatnei jābūt pilnībā sacietējušai, tīrai un konstrukcionāli stabilai. Tai jāatbilst līdzenuma pielaidēm un nedrīkst būt plaisu, kustības vai mīkstu zonu pazīmju.

Kad šie nosacījumi ir izpildīti, laukuma seguma un groza uzstādīšana kļūst vienkārša.

Kam būtu jāizbūvē pamatne?

Lai gan daudzas basketbola laukumu virsmas var uzstādīt pašu spēkiem, pamatnes izbūvi vislabāk uzticēt pieredzējušiem zemes darbu speciālistiem. Šis posms prasa atbilstošu aprīkojumu, zināšanas par vietējiem grunts apstākļiem un izpratni par pielaidēm, kas pārsniedz vispārējos labiekārtošanas darbus.

OnCourt nodrošina tehniskos rasējumus un specifikācijas, lai vietējie būvnieki varētu pareizi izbūvēt pamatni bez minējumiem. Šī pieeja apvieno vietējo pieredzi ar skaidriem veiktspējas standartiem.

BUJ par basketbola laukuma pamatni

Apakšklājs ir sablīvēts pamatslānis zem jūsu laukuma virsmas. Tas atbalsta modulāro flīžu sistēmu, absorbē slodzi, novērš kustību un nodrošina vienmērīgu basketbola atlēcienu. Bez stabila apakšklāja laukums var pārvietoties, laika gaitā veidoties nedzīvām vietām vai slikti drenēties.

Ierakuma dziļums ir atkarīgs no substrāta, grunts apstākļiem un klimata, bet parasti tas ir no 100 mm līdz 250 mm. Mīkstā augsnē vai aukstākā klimatā var būt nepieciešams ierakt dziļāk, lai novērstu sala izraisītu pacelšanos un nosēšanos.

Parastais pamatnes uzbūves veids ietver:

– 1. tipa MOT (šķembas) sablīvēšanai un drenāžai

– Sablīvēta asa smilts slānis vai smalks apakšslānis

– Pēc izvēles, ģeotekstila audums nezāļu apkarošanai un stabilitātei

Lai iegūtu vislabākos rezultātus, uzstādot moduļu flīžu sistēmas, pabeidziet darbu ar gludu betona vai asfalta pamatni. Kā aprakstīts šajā rakstā, līdzenuma pielaide ne vairāk kā 5 mm jebkurā 3 m rādiusā nodrošinās lielisku veiktspēju.

Jūsu pamatne jābūt izlīdzinātai ar precizitāti līdz 5 mm jebkurā 3 m rādiusā. Šī pielaide ir ļoti svarīga, lai nodrošinātu, ka jūsu moduļu flīzes ir droši savienotas un nodrošina drošu, vienmērīgu spēles pieredzi.

Jā. Lai novērstu ūdens uzkrāšanos zem moduļu seguma, ir nepieciešama atbilstoša drenāža. Āra kortiem nepieciešams izveidot nelielu slīpumu, caurlaidīgus pamatnes slāņus vai drenāžas kanālus.

Jā, ja esat pārliecināts par savām izrakšanas un sablīvēšanas prasmēm. Daudzi amatieri paši veic pamatnes izveidi, bet lielākiem vai sarežģītākiem kortiem mēs iesakām sadarboties ar profesionālu būvuzņēmēju.

Sadarbība ar vietējo zemes darbu veicēju parasti ir gudrs lēmums. Viņi ir labāk aprīkoti, lai novērtētu vietējos augsnes apstākļus, izprastu reģionālos drenāžas izaicinājumus un var efektīvāk mobilizēt atbilstošas iekārtas un materiālus. Profesionāli sagatavota pamatne arī sniedz pārliecību, ka jūsu laukums darbosies vislabākajā veidā daudzus gadus.

Mega Slam Hoop zemes basketbola groza uzstādīšana ir divu posmu darbs. Tiek izrakts 1,25 m dziļš caurums, kurā tiek ievietots betona enkurs, kas atbalsta sistēmu. Nākamais posms ir groza uzstādīšana. Mega Slam Hoops grozi ir smagi – tieši tas padara tos par ideāliem mājas groziem. Tas nozīmē, ka jums būs nepieciešama draugu palīdzība, lai paceltu smago grozu. Uzzināt vairāk par Mega Slam Hoops instalācija.

PIEZĪME – Grozu sistēma un komponentu stiprinājuma mezgli jāuzstāda pamatnes būvniecības laikā. Konfigurējiet un pasūtiet savu laukumu, grozu un komponentus, lai nodrošinātu, ka zemes stiprinājuma mezgli ir pieejami pamatnes būvniecības laikā.

Nākamie soļi

Kad pamatne ir pabeigta, varat pāriet no zemes darbiem uz laukuma montāžu.